MIL-DTL-21083E(MC)

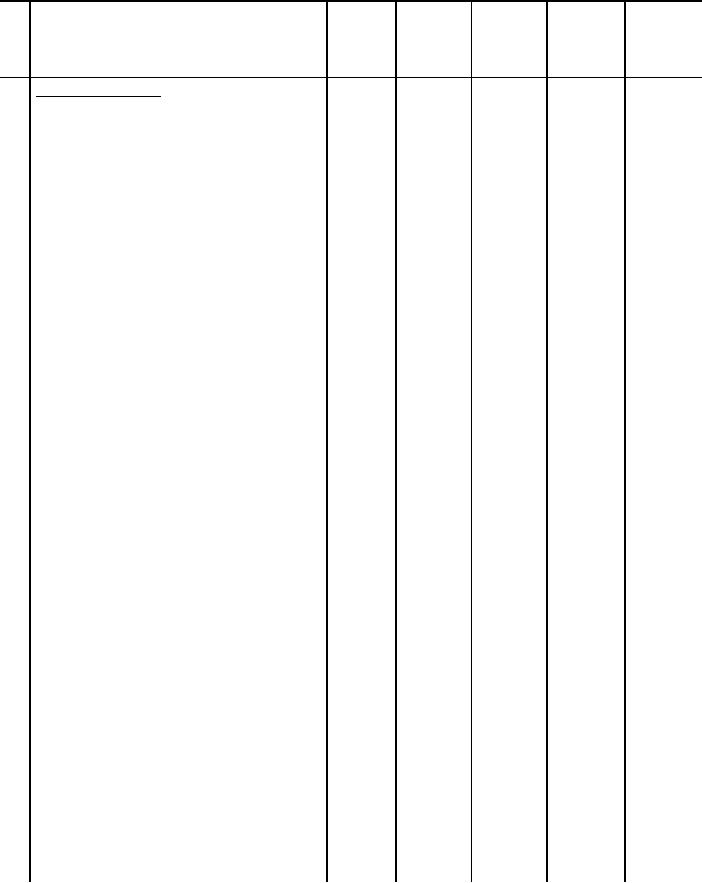

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

4 Assemble fronts. (cont'd)

0

b. Fold the upper fronts,

301

SSa-1

10-14

A

A

matching the cut edges of the

waist dart, and stitch the entire

length of the dart 3/8 inch from

the cut edges at the lower end and

tapering to a point one inch from

the end of cut at the upper end.

c. Position the upper front and

301

SSa-1

10-14

A

A

side-body panel with edges even

and join with a 3/8 inch seam.

d. Spread open the waist dart and

the underarm seam and press flat

with a heated pressing iron.

e. Position the upper and the

301

SSa-1

10-14

A

A

lower fronts with edges even and

join together at the waist with a

3/8 inch seam and with the 1/4

inch wide stay tape positioned on

the upper fronts 1/4 inch from the

edge and caught in the stitching.

Backtack the front end of seam on

the left front for a distance of

not less than 1-1/2 inches.

NOTE: The tape may be sewn

simultaneously in the joining seam

of the waist; or the tape may be

sewn to the upper fronts prior to

joining the skirt to the upper

front.

f. The tape shall be sewn with

normal tension, not loose or

tight, and shall extend from the

front edge of the fronts.

g. Spread open the waist seam and

press flat with a heated pressing

iron.

h. Press and shape the fronts,

from the waist to the top edge, on

a suitable type heated pressing

machine, shrinking the fronts to

eliminate the excess fullness of

the chest.

44

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business