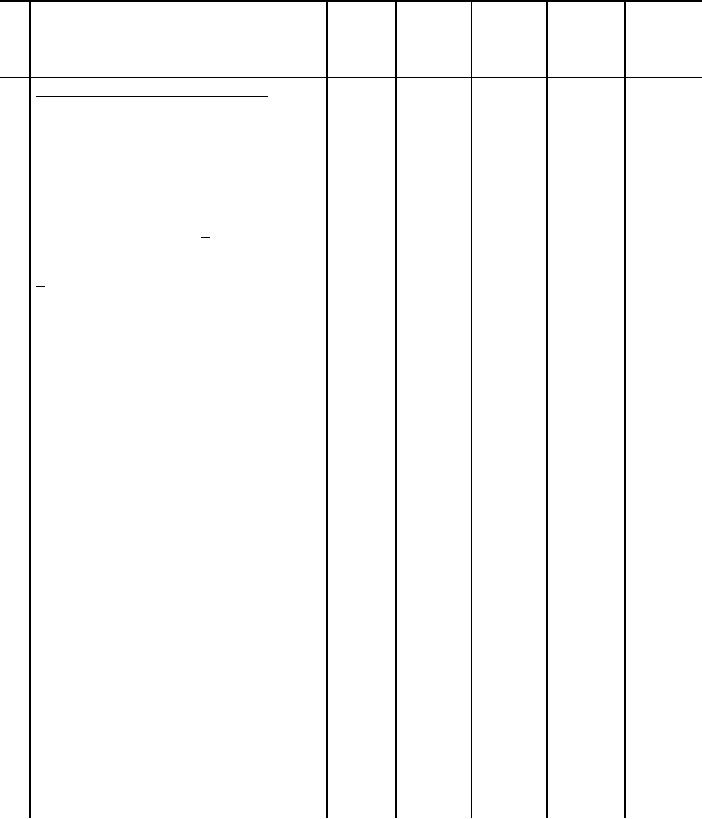

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

3 Join backparts and tape neck.

5

Finished appearance. The backs

shall be joined without gathers,

puckers or plats. The folded edge

of the left vent shall be in line

with the center back seam. In the

finished coat, the left backpart

shall overlap the right backpart

not less than 3-1/2 + 1/4 inches,

measured at the bottom edge of the

coat, and left vent shall be 1-1/2

+ 1/8 inches wide measured at the

bottom bound edge. Stitch the 1/4

inch wide stay tape to the inside

of left center back along the

vent, with the edge of tape

positioned approximately 1/8 inch

in front of the fold notch of the

vent.

a. Position the backparts with

301

SSa-1

10-14

A

A

edges even and join at the center

with a 5/8 inch seam from the top

edge of the backs to approximately

3/4 inch below top end of the

vent. From that point, continue

to stitch diagonally across the

top end of the left and right

vents to the bound edge of the

backs.

b. Turn the left vent to the

301

OSf-1

10-14

A

A

inside of the left backpart in

(silk)

(silk)

accordance with the notches and

edgestitch uniformly 1/8 inch from

the folded edge. The folded edge

of vent shall be in line with the

center back seam.

c. Sew a 1/4 inch wide tape to

301

SSa-1

10-14

A

A

the inside neck of the back, 1/4

inch from the top raw edge and 5/8

inch from each shoulder edge. The

tape shall be sewn flat and the

center back seam shall be open.

41

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business