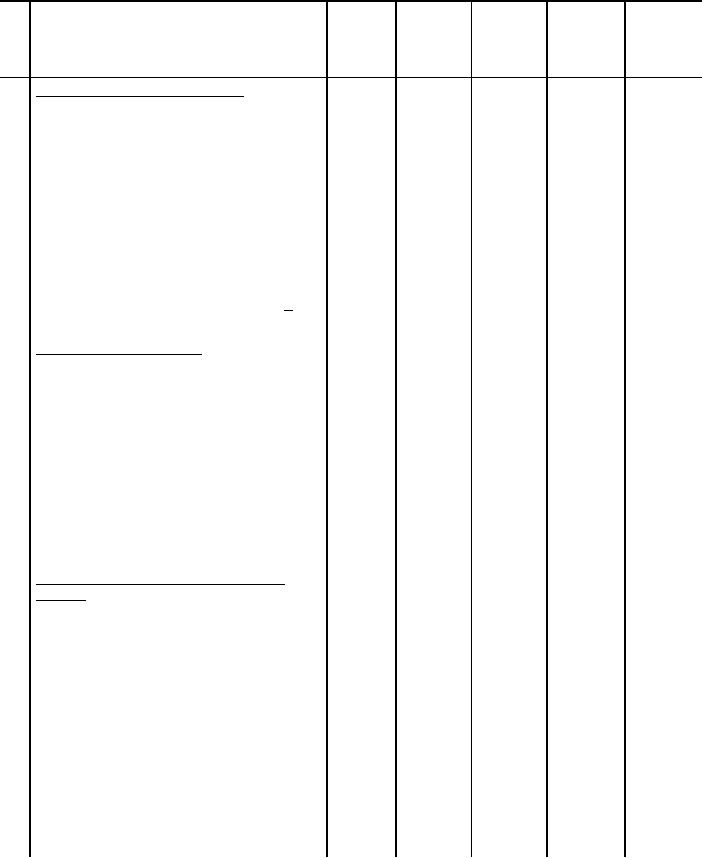

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

2 Hem yoke and front lining.

6

Finished appearance. The hem

shall be uniformly stitched,

uniform in width, and shall finish

smooth and flat without twists,

gathers, puckers or pleats.

a. Hem the bottom edge of

the

301

EFb-1

10-14

A

A

yoke and front linings,

respectively, with the raw

edge

turned under. Stitch 1/16

inch

from the folded upper edge

of hem.

b. The hem shall measure 3/8 +

1/8 inch wide.

2

Make armhole shields.

7

Finished appearance. The armhole

shields, of one ply of basic

material, shall finish without

puckers, gathers, or raw edges.

a. Bind the rounded edge of

301

BSb-1

10-14

A

A

shield with bias binding, turning

under the outside raw edge of the

binding only and catching the

turned under portion in the

stitching 1/16 inch from folded

edge.

2 Make center pleat in back yoke

8 lining.

Finished appearance. The pleat

shall be uniform in width and

shall finish smooth and flat

without puckers or pleats.

a. Fold the back yoke lining, in

301

OSf-1

10-14

A

A

accordance with the notches on the

pattern, to form a 5/8 to 3/4 inch

wide pleat at the center back.

Tack lengthwise along the pleat in

line with the notches for a

distance of 1 to 1-1/2 inches from

the top end.

-or-

34

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business