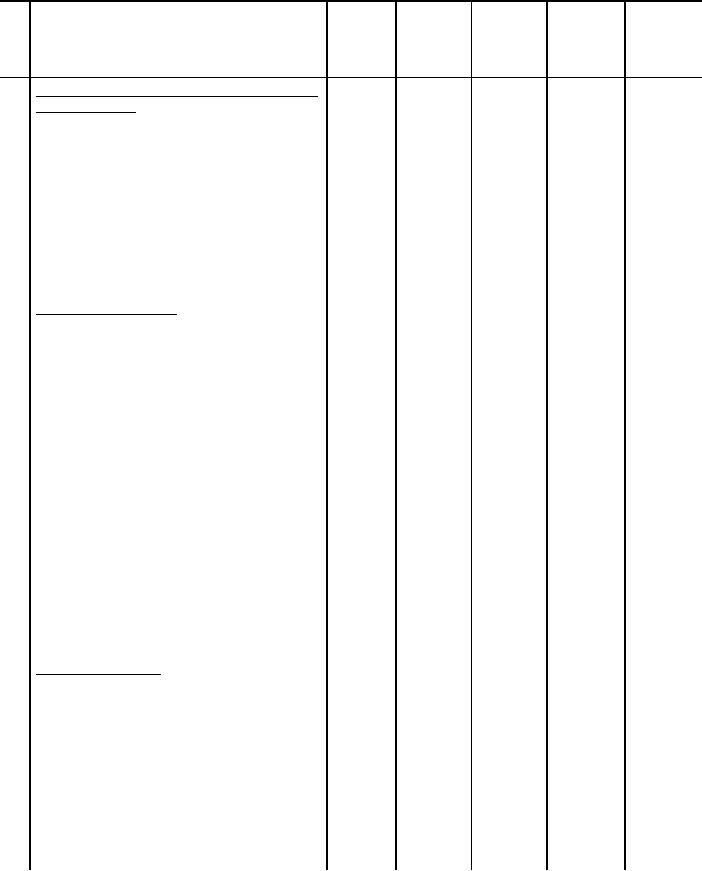

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

Seam reinforcement stay to armhole

3

8

and shoulder. (cont'd)

a. Seam the 3/4 inch wide

301

SSaa-1

10-14

A

A

polyester cotton stays to the

underside of the fronts along the

shoulder edge and upper front edge

of the armhole, respectively, 1/8

inch from the outer edges. The

top end of the armhole stay shall

form a right angle at the armhole

without the stays overlapping each

other.

3 Bind lower fronts.

9

Finished appearance. The binding

shall be uniformly stitched, shall

not be tight or full causing

puckers, gathers or pleats and the

basic material and edges of

binding shall be securely caught

in the stitching. The outside raw

edge only of the binding shall be

turned under and caught in the

stitching.

a. Bind the raw back edge of the

301

BSb-1

10-14

A

A

lower fronts with bias binding,

turning under the outside raw edge

of binding only and catching the

turned under portion in the

stitching 1/16 inch from the inner

folded edge. The binding shall

extend from the waist seam to the

bottom edge of fronts.

4 Assemble fronts.

0

Finished appearance. The waist

darts shall be properly tapered

and shall finish without gathers,

puckers or pleats. The upper and

lower front and side body panel

shall be joined without gathers,

puckers or pleats.

a. The fronts shall consist of an

upper front, a side body panel,

and a lower front (skirt).

43

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business