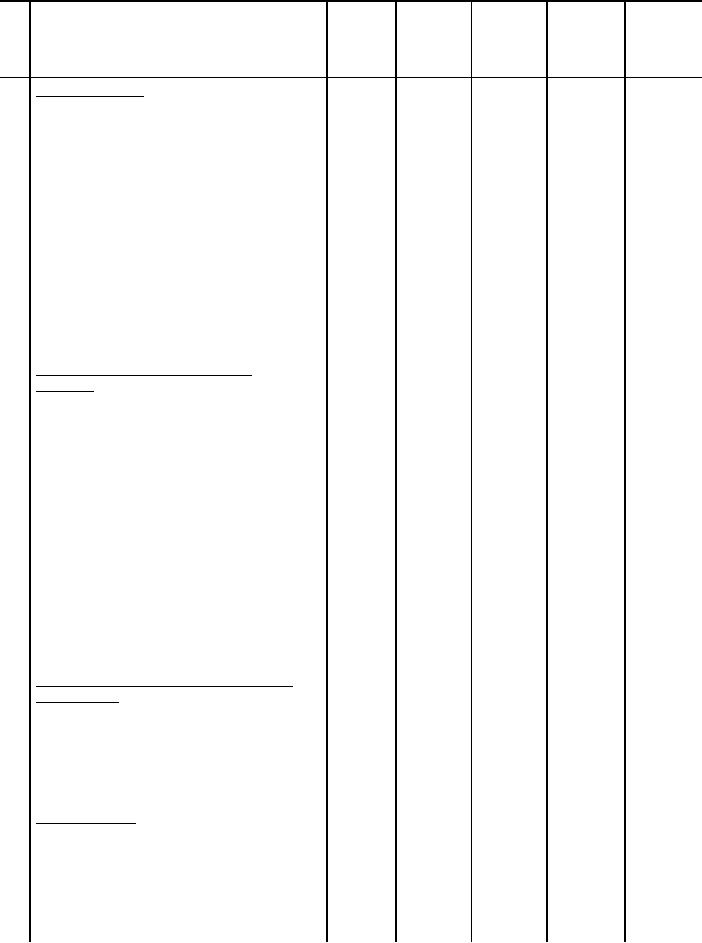

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

4

Tape armholes.

9

301

SSaa-1

10-14

A

A

a. Sew 1/4 inch wide tape around

the armhole from a point 1 to

or

1-1/2 inches to 3/4 to 1 inch

401

above notch on the fronts from

shoulder edge on the back.

b. From the front notch to 1-1/2

301

SSaa-1

10-14

A

A

to 2 inches back of the underarm

or

401

seam, the tape shall be stitched

with slight tension and from this

point up to 1-1/2 to 2 inches

above the notch on the back, the

tape shall be held taut while

stitching and gathering 1/4 to 3/8

inch fullness.

Sew snap fastener to upper

5

0

pockets.

Finished appearance. The pockets

shall lie smooth and flat without

distortion when closed.

a. Securely sew one socket snap

101

21 per

A

fastener part to each side edge of

fastene

the upper pockets to engage stud

or

r (min)

A

A

part of flaps. When socket part

301

16 per

is sewn by hand, the stitching

fastene

shall be tacked off with not less

or

r (min)

C

than two stitches.

Hand

3-4

(silk)

double

thread

(not

incl.

tack)

5 Press armholes, shoulder blades

1 and lapels.

a. Press the armhole tapes, the

shoulder blades and the lapels

smooth and flat with a heated

pressing iron or suitable type

pressing machine.

5

Shape fronts.

2

a. Mark and shape the front edge

of the coat; and mark and shape

the lapels in accordance with

shaper furnished. The left front

edge shall be dressed from bottom

notch of coat to base of lapel.

52

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business