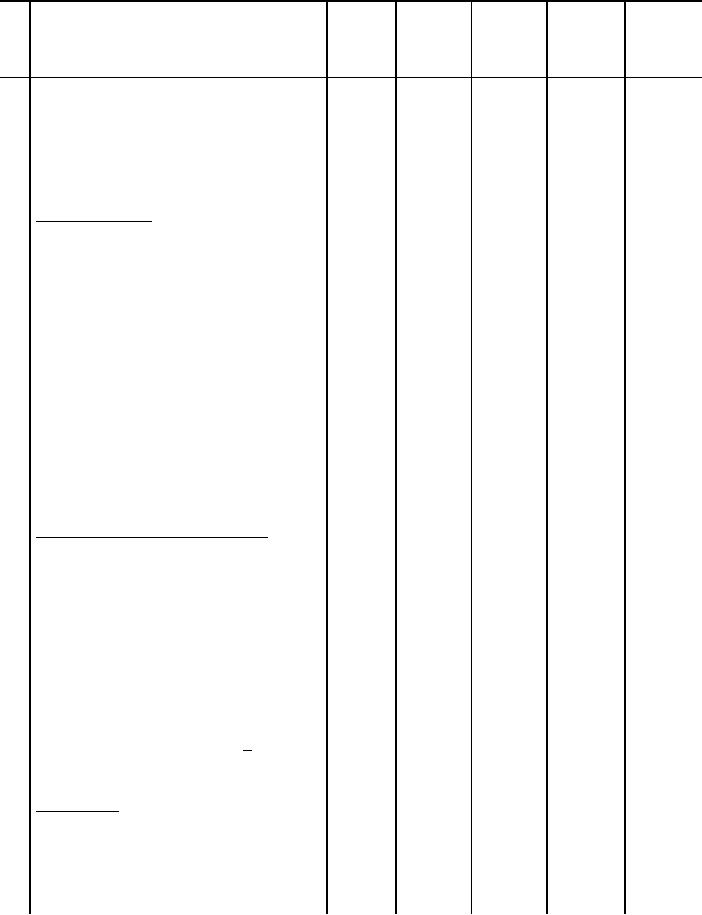

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

b. Turn raw edge of yoke lining

Hand

(Commer-

at the shoulders. Baste the upper

or

cial)

part of each shoulder over the

301

front lining and continue to baste

across neck at back with the end

of the back pleat caught in the

basting.

Baste shoulder.

6

(cont'd)

6

c. In lieu of basting the lining

301

SSa-1

10-14

A

A

at the shoulder as required in

66.a and b, and handfelling as

required in 79.g, trim the

shoulder edge of the front lining

and yoke lining to approximately

3/8 inch from shoulder at the

armhole edge and tapering to 1/8

inch at the neck. Join the yoke

lining to the facing-lining

assembly at the shoulder with a

3/8 inch seam, working in the

proper fullness on the back. In

the finished coat, the yoke lining

shall be lapped on the

facing-lining assembly at the

shoulder.

6

Stitch hanger and size label.

7

Finished appearance. The size

label and the ends of the coat

hanger shall be centered and sewn

to the inside center back of the

coat at the neck.

a. Stitch the upper edge of the

301

SSa-1

10-14

A

A

size label and the ends of the

hanger to the inside center back

of the coat at the neck.

b. The hanger opening in the

finished coat shall be 2 + 1/8

inches long when measured along

the lower edge of the collar.

6

Set collar.

8

Finished appearance. The collar

shall finish centered on the back

seam with the fullness distributed

over the shoulder to conform to

and hug the neck.

60

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business