MIL-DTL-21083E(MC)

TABLE I.

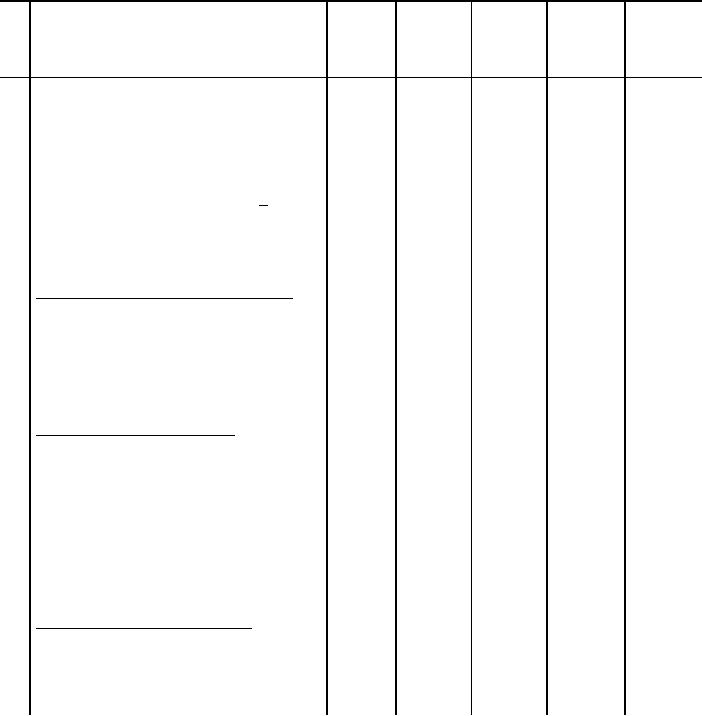

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

c. Baste the under collar to the

Hand

(Commer-

front and back, placing proper

or

cial)

fullness over shoulder.

Machin

e

d. In the finished coat, the ends

of the collar and top edge of

lapels shall each be 1-5/8 + 1/8

inches when measured from the

tacked corners to the finished

edges of collar and lapel,

respectively.

Tack collar interlining to coat.

7

1

a. Raise the lower edge of the

Hand

2-3

C

top collar and tack the collar

or

(silk)

interlining to upper edge of the

103

SSm-1

3-4

0

coat and the yoke lining with

or

(silk)

overcast stitching from shoulder

301

SSm-1

3-4

0

0

seam to shoulder seam.

(silk)

(silk)

7

Baste top collar to coat.

2

a. Turn under the lower edge of

Hand

(Commer-

the top collar and baste across

or

cial)

neck.

301

-or-

b. In lieu of operations 71.a and

301

SSa-1

10-14

A

A

72.a, join lower edge of top

collar from gorge seam to gorge

seam across neck.

7

Edgestitch coat and collar.

3

Finished appearance. The coat

shall be uniformly edge stitched

the same gage as used on flaps and

pockets.

62

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business