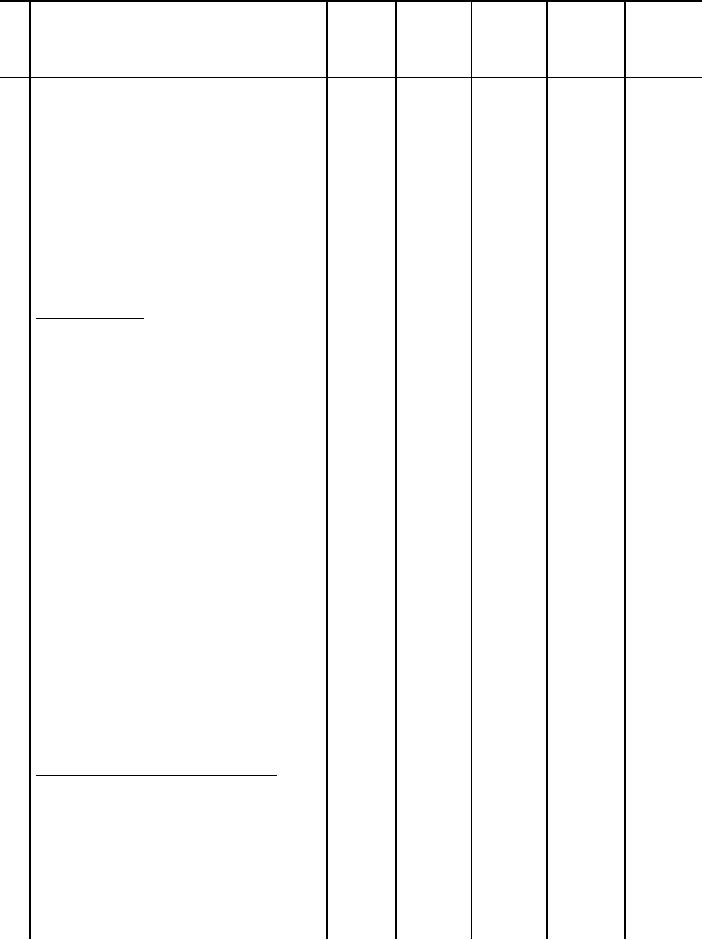

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

c. Press the entire armhole

smooth and flat with heated

pressing iron to remove the

fullness. Press and remove the

fullness using a heated iron from

the upper part of the armhole

sleeve seam from backarm sleeve

seam over the shoulder area to

approximately midway between

shoulder and the notch at front

edge of armhole, so that the

sleeve seam finishes smooth and

flat.

7

Baste armhole.

5

a. Position shoulder pad to

301

(Commer-

armhole and baste around outside

or

cial)

of armhole, with the stitches

Hand

adjacent to and no more than 1/8

inch away from armhole seam,

forcing out the armhole in the

basting so that all fullness is

removed from basic material

between the lapel and armhole.

Care shall be taken not to catch

yoke or front lining in the

basting on the inside of armhole.

The basting stitches shall extend

from the backarm seam of the

sleeves to the front notch of the

coat. Turn coat to inside.

b. Baste around inside armhole,

301

(Commer-

positioning yoke lining and front

or

cial)

lining in place to inside of coat

Hand

front interlining and shoulder pad

around armhole, distributing

fullness evenly so that armhole

finishes smooth and without

fullness, puckers, twists or

pleats.

7

Baste underarm shield to coat.

6

a. Position the underarm shield

on lining side of coat with raw

edges even with lower edge of

armhole.

b. Baste or tack underarm shield

301

(Commer-

at the base of armhole. The

or

cial)

shield shall not cover the opening

Hand

of the inside pocket.

64

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business