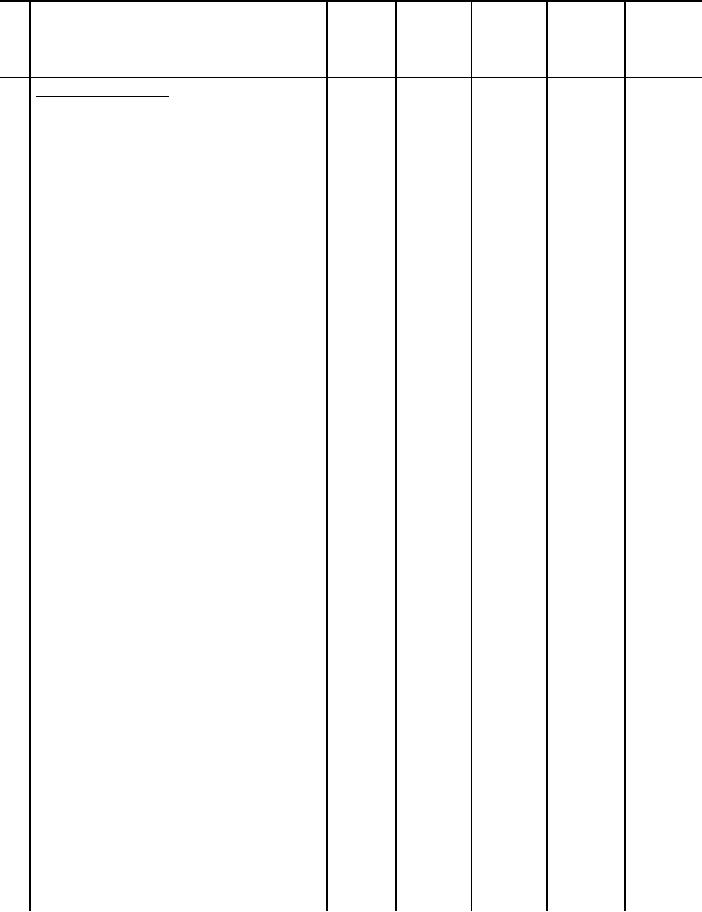

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

8

Make buttonholes.

3

Finished appearance. The

buttonhole shall be clean cut,

well made, properly positioned,

well worked over gimp to fit a

40-line insignia button and the

34-line sewing hole button. The

stitching shall be securely caught

in the basic material. The gimp

shall be pulled through to the

underside of the front and the

purling of the buttonholes shall

be on the outside. The waist seam

shall not be open beyond the end

of the waist buttonhole.

a. Mark the left front in

accordance with the marks on the

pattern for the location of four

buttonholes. The mark for the

bottom buttonhole shall be on the

waistseam, the top buttonhole

shall be on horizontal line with

the eyelet of the buttonhole in

the upper pocket flap, and

remaining two buttonholes shall be

evenly spaced.

b. Make one horizontal eyelet

Button

50 per

B

F

end, square-bar type, cut-first

-hole

(silk)

(silk)

button-

buttonhole, 1-1/8 inches long, at

hole

each of the marks, with the

purling of the buttonhole to

(min)

finish on the outside of the

(not

front. The inside edge of the

incl.

tack)

eyelet end of the buttonhole shall

be 5/8 inch from front edge. The

buttonhole shall be well worked

over gimp and the ends of the gimp

shall be pulled through to the

underside.

c. Care should be exercised when

making the buttonhole in the

waistseam, so that the seam does

not come open beyond the ends of

the buttonhole.

d. Securely bartack the ends of

Bartac

21 per

B

F

each buttonhole and trim the ends

k

bartack

(silk)

(silk)

of the gimp and thread.

(min)

70

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business