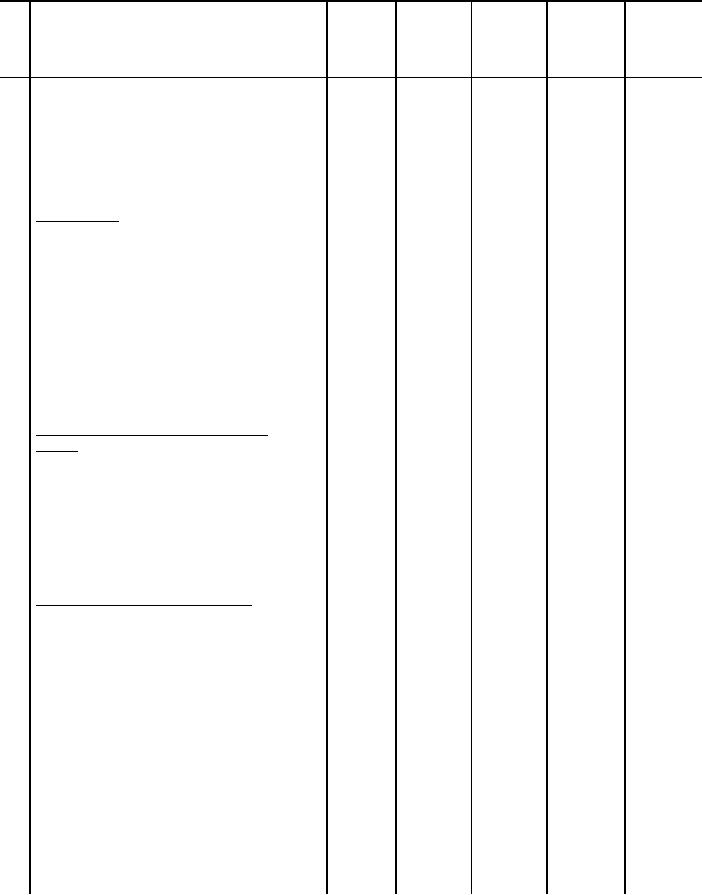

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

a. Mark the coat on the outside

around the neck from shoulder seam

to shoulder seam 5/8 inch from top

edge, and continue to mark along

the gorge with the line of marking

tapering to 3/8 inch at the lapel

notch.

Set collar.

6

(cont'd)

8

b. Join the top collar to the

301

SSa-1

10-14

A

A

facing at the gorge from the lapel

notch to a point not less than one

inch in back of the lapel

breakline.

c. Notch the facing at the end of

the gorge seam, in back of the

lapel breakline, the width of the

seam without cutting the stitching

of the seam.

6

Tack top collar to fronts at

9

gorge.

a. Spread open the seam joining

Hand

2-4

C

top collar to facing and tack the

or

(silk)

seam allowance of the top collar

301

SSa-1

10-14

A

A

to the front at the gorge from the

lapel notch to the end of the

seam, catching the top end of

bridle tape in the tacking.

7

Baste under collar to coat.

0

Finished appearance. The center

seam of the under collar shall be

in line with center back seam of

coat. Fullness in the collar

shall be properly placed over the

shoulders to permit the collar to

lie flat.

a. Turn the collar to the outside

with the lower neck of the under

collar lapped on the outside of

the coat at the mark.

b. Securely tack the corners of

Hand

5-8 per

C

the collar across the juncture

or

tack

(silk)

point of the collar and the lapel.

Machin

e

61

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business