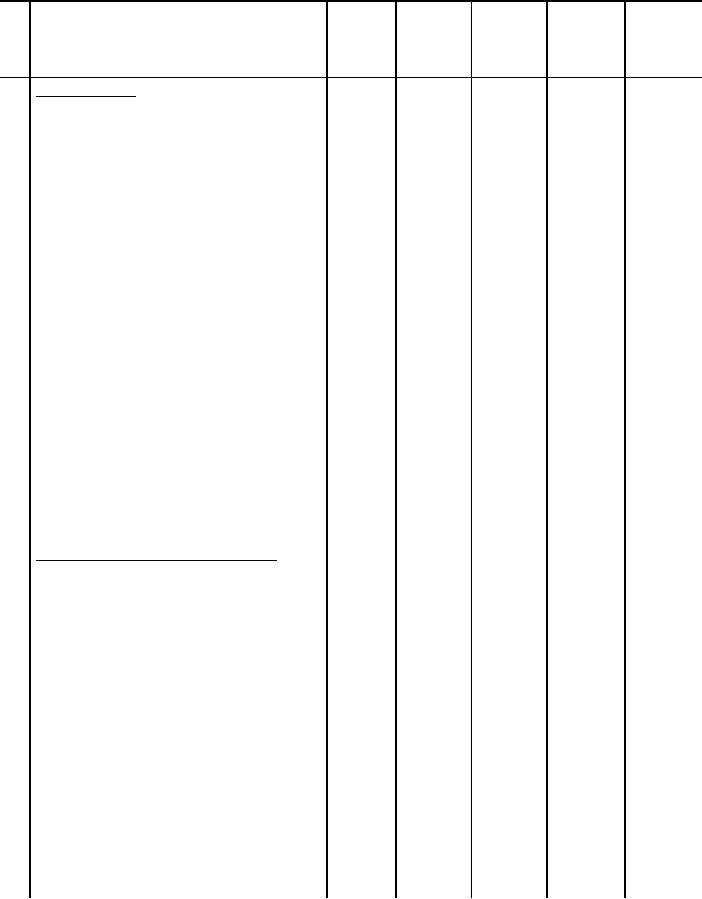

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

7 Fell linings. (cont'd)

9

d. Fell the lower corners of the

Hand

C

8-10

front lining to the facings and

(silk)

the front seam allowance. As an

12 per

C

alternate, operation 76.d and 76.e

tack

(silk)

may be performed by machine with

one blind tack on each corner.

e. Fell the upper back edge of

Hand

8-10

C

the front lining to the yoke

(silk)

lining, placing the stitching over

the folded edge of the front

lining. Fell the lower finished

edge of the yoke lining to the

side seam allowance. As an

alternate, this operation may be

performed by machine with two

blind tacks on each side.

f. Tack bottom edge of armhole

Hand

4 per

C

shields on the underside to

tack

(silk)

lining.

(min)

g. Fell the back lining and

Hand

8-10

C

facing lining assembly together at

or

(silk)

the shoulders, placing the

Machin

10-12

stitching over the folded edge of

e

back lining.

301

8

Tack facing and bottom turnup.

0

a. Fell the ends of the bottom.

Hand

8-10

C

Turnup to the body of the coat at

(silk)

the vent.

b. Fell the back edge of the

Hand

8-10

C

facings to the coat from the

(silk)

bottom to the top edge of the

bottom turnup. As an alternate,

operations 80.a and 80.b may be

12 per

performed by machine with two

tack

blind tacks on each vent.

c. Tack the facings on the

Hand

4-6

C

outside to the front edge of the

(silk)

inside pocket through the

interlining with a hidden

backstitch, extending for a

distance of 5 inches down from,

and in line with, the front end of

the pocket opening.

68

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business