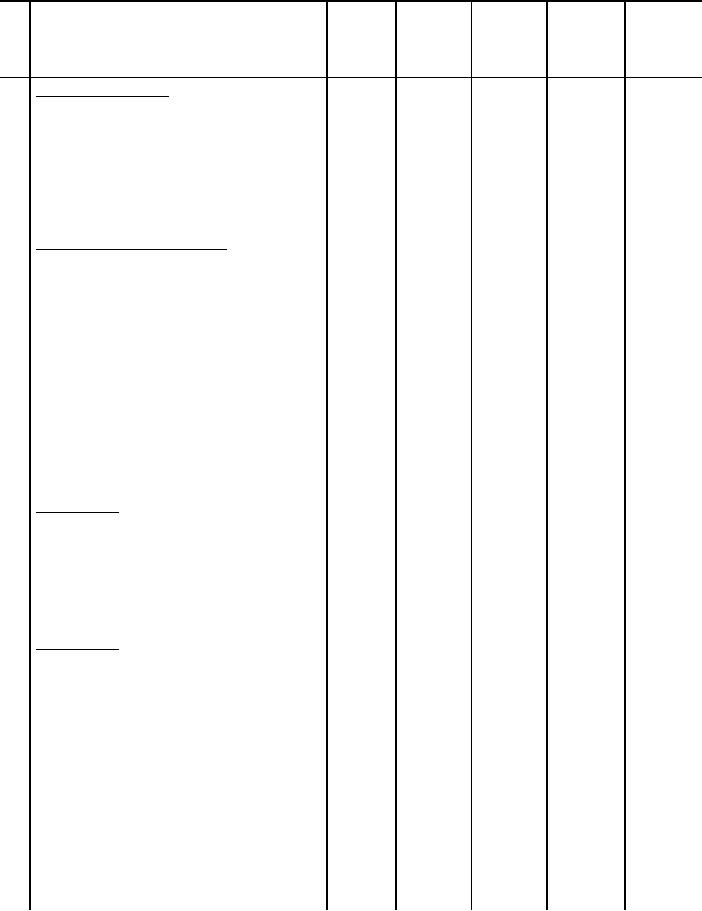

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

8 Make buttonholes. (cont'd)

3

e. An automatic one-cycle

buttonhole/bartack machine with

cut-first attachment may be used

to make the required eyelet-end,

square bar type buttonholes.

Stitches and thread requirements

remain the same.

8

Make eyelets in pockets.

4

Finished appearance. The eyelets

shall be worked with the purling

on the outside of the pocket and

shall finish 1/8 inch in diameter

opening. All stitches shall be

securely caught in fabric.

a. Make one eyelet in each pocket

Eyelet

21 per

A

A

for removable insignia button, to

eyelet

(silk)

(silk)

correspond with eyelet-end of

buttonhole in flaps so that when

buttoned on the finished coat,

flaps shall be smooth and flat

without twists or bulges.

8

Clean coat.

5

a. Pull and remove all basting

threads. Trim and remove all

loose ends of thread and remove

all spots, stains and shade

tickets and markings without

injury to the material.

8

Press coat.

6

Finished appearance. The coat

shall be well pressed throughout

with a heated pressing iron or

pressing machine of a type

suitable to obtain the desired

shape and appearance in accordance

with good manufacturing practices.

a. Press the fronts smooth and

flat, straightening and shaping

the front edges and working the

fullness towards the chest. Care

shall be exercised in pressing the

fronts so that the bottom edges

are even.

71

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business