MIL-DTL-21083E(MC)

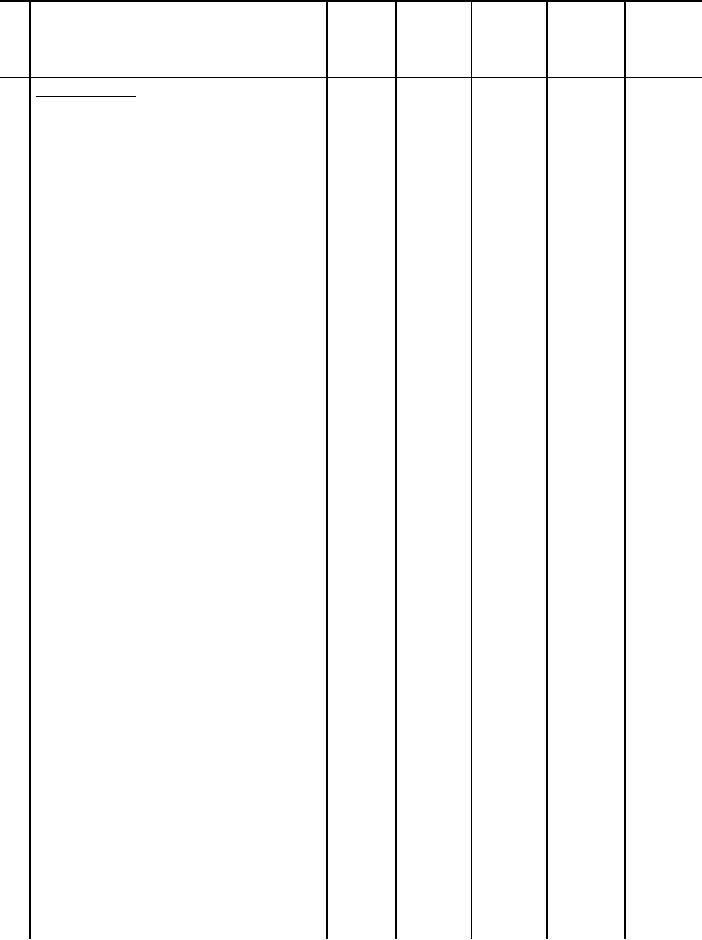

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

7

Fell linings.

9

a. Position the sleeve lining at

Hand

8-10

C

the armhole with back and forearm

(silk)

seams of sleeves and linings

matched. Turn under the armhole

edge of the sleeve lining and lap

the lining on the outside of the

front and yoke linings at the

armhole. Fell the sleeve lining

to the coat around the entire

armhole, placing the stitching

over the folded edge of sleeve

lining, distributing the fullness

along the bias front of the

armhole and back of armhole from

shoulder seam area to 1 to 2

inches below backarm seam and back

stitching the lower armhole edge

from approximately 1-1/2 inches to

the front of forearm sleeve lining

seam to the side seam of body

lining.

-or-

As an alternate, the armhole

lining may be felled utilizing a

sleeve lining felling machine that

consists of a feed off the arm

machine equipped with a lower and

upper feed (review specification

requirements for felling of sleeve

lining in relation to appropriate

turn under).

(1) Stitch sleeve lining to

301

SSa-1

10-14

50

50

armhole on inside of front sleeve

notch to backarm seam across under

sleeve.

(2) Stitch the top lining to

306

SSa-1

10-14

50 or

50 or

armhole on inside from the front

mercer-

mercer-

armhole notch to top back arm

ized

ized

lining seam across the crown of

cotton

cotton

the top sleeve lining.

50/2

50/2

or

or

3

3

or

or

Nylon A

Nylon A

(3) Close the previous left

301

SSc-1

10-14

50

50

opened forearm seam 1/16 to 3/32

inch from edge.

66

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business