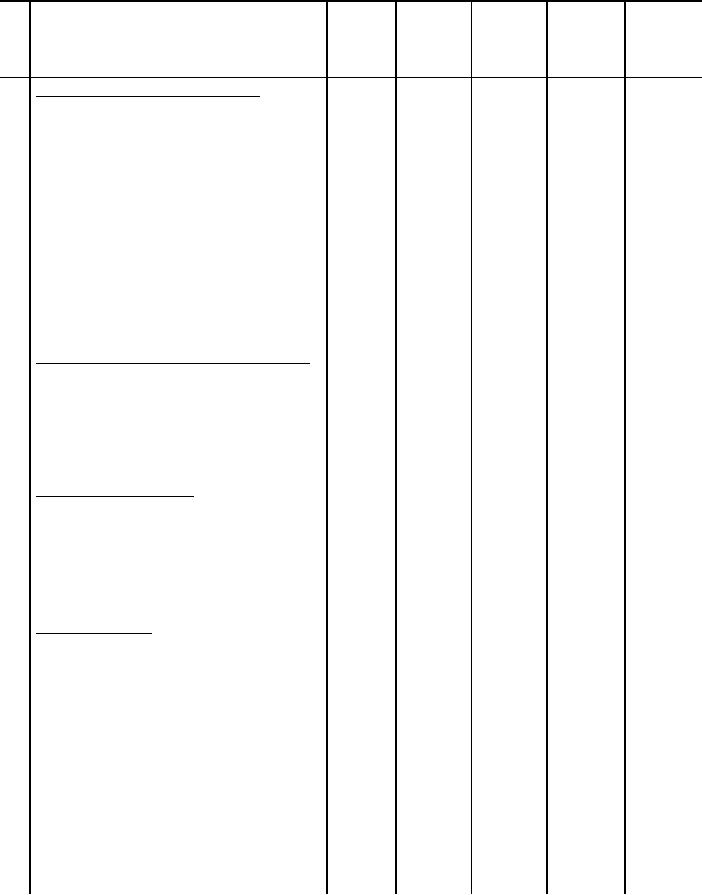

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

6 Baste and fell front lining.

1 (cont'd)

e. Fell the turned-under portion

103

EFc-1

6-8

0

0

of the front lining to side seam

or

(b)

(silk)

(silk)

allowance of the fronts and to the

Hand

8-10

C

yoke lining with blind stitching

(silk)

1/4 to 3/8 inch from folded edge.

Stitching shall extend from bottom

finished edge of front lining to

the lower edge of armhole. The

blind stitching shall not be

exposed on the face side of the

lining nor shall the blind

stitching be exposed on the

outside of front (basic material).

Trim front lining and interlining.

6

2

a. Trim the excess coat front

interlining and front lining at

the armhole.

b. Trim the yoke lining even with

the back at the neck.

6

Baste shoulder pads.

3

a. Insert shoulder pad between

301

(Commer-

interlining and chest padding of

or

cial)

coat front interlining in line

Hand

with the armhole edge and securely

tack pad to the interlining and

chest padding only.

6

Seam shoulders.

4

Finished appearance. The shoulder

seam shall be uniformly stitched

and the fullness on the backs

shall be properly placed in order

that the shoulder may be properly

shaped. The shoulder seam shall

finish without a distorted

appearance.

a. Join the fronts and back

301

SSa-1

10-14

A

A

together at the shoulders with a

or

3/8 inch seam, working in the

401

SSa-1

10-14

A

A

proper fullness on the backs in

accordance with good manufacturing

practice.

58

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business