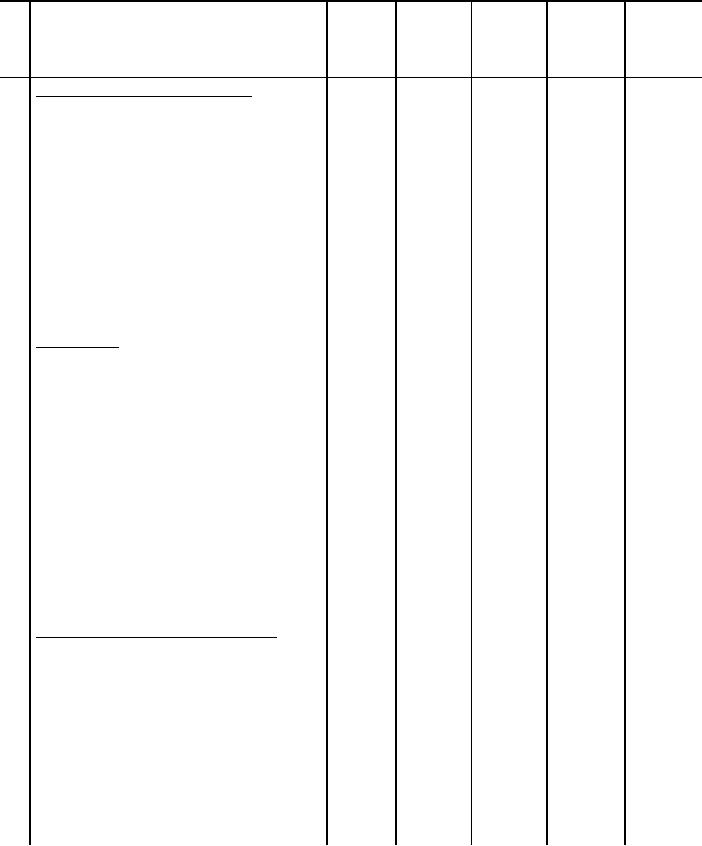

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

4 Baste bridle tape to lapel.

6 (cont'd)

b. Baste the tape evenly and

301

(Commer-

smoothly for a distance of 1-1/2

or

cial)

to 2 inches down from the gorge;

Hand

continue basting for a distance of

4 to 5 inches, holding the tape

taut and working in 3/8 to 1/2

inch breast fullness. Baste the

remainder of the tape evenly,

smoothly and without tension or

fullness. Tape and interlining

shall be stamp marked to assure

proper fullness.

4

Pad lapels.

7

a. Pad each lapel from

103

SSm-1

4-8

000

approximately 1 inch from the

or

front edge to the breakline with

306

000

000

six rows of blind stitching,

properly distributing the fullness

in the interlining between the row

of stitches to roll the lapels.

b. Blind stitch both edges of

103

SSm-1

4-8

000

bridle tape to interlining.

or

306

000

000

c. Press the left and right

fronts on a suitable type heated

pressing machine, with the chest

to conform to shape of the body.

4

Join back and fronts at sides.

8

Finished appearance. The back and

fronts shall be carefully joined

at the sides without twists,

gathers, puckers or pleats.

a. Position the back and fronts

301

SSa-1

10-14

A

A

with edges even and join together

or

at the sides with a 3/4 inch seam.

401

SSa-1

10-14

A

A

b. Spread open the side seams and

press flat with a heated pressing

iron.

51

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business