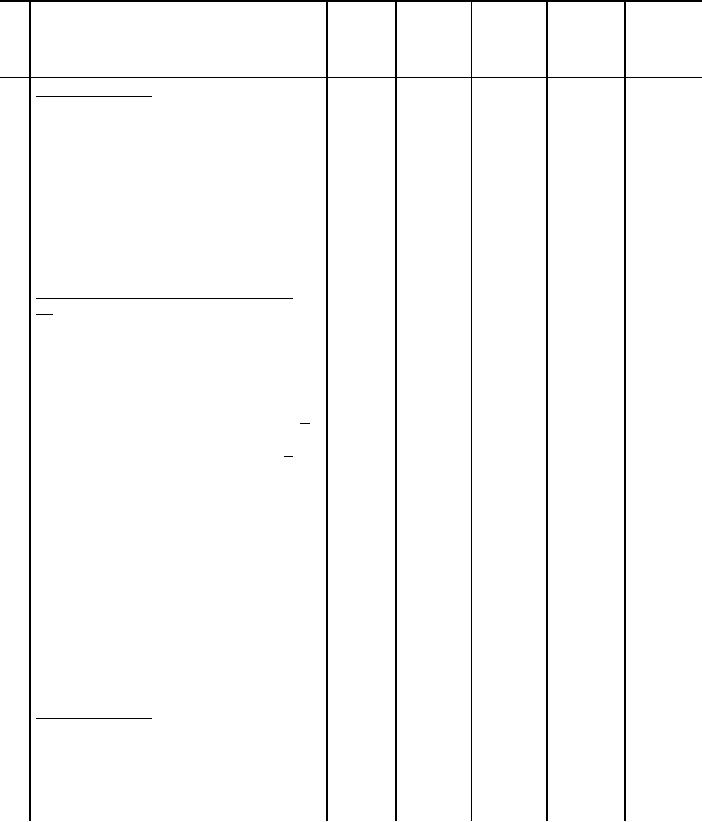

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

6

Seam shoulders.

(cont'd)

4

b. Spread open the shoulder seam

and press flat, holding the

shoulder short and exercising much

care in the pressing in order not

to effect a distorted appearance

in the finished seam. The

pressing shall be accomplished

with a heated pressing iron or

pressing machine over a suitable

block.

6

Set shoulder straps (see Figure

5

4).

Finished appearance. The shoulder

strap shall be properly positioned

and uniformly stitched to the coat

without twists, puckers, pleats or

other distortion. On the finished

coat, the straps shall be 2-3/8 +

1/8 inches wide at the armhole

seam and shall taper to 1-3/4 +

1/8 inches at buttonhole eyelet

end.

a. Position the shoulder straps

with the pointed end of the strap

even with the edge of the neck,

and with the seam of shoulder

strap matching the shoulder seam

at the armhole edge.

b. Seam the shoulder straps to

301

SSa-1

10-14

A

A

the coat 1/8 to 1/4 inch from the

armhole edge. Trim the shoulder

strap even with the armhole, where

necessary.

6

Baste shoulder.

6

a. Position shoulder interlining

Hand

(Commer-

and lining in place, baste upper

or

cial)

part of each shoulder on the

301

outside and turn the coat on the

inside.

59

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business