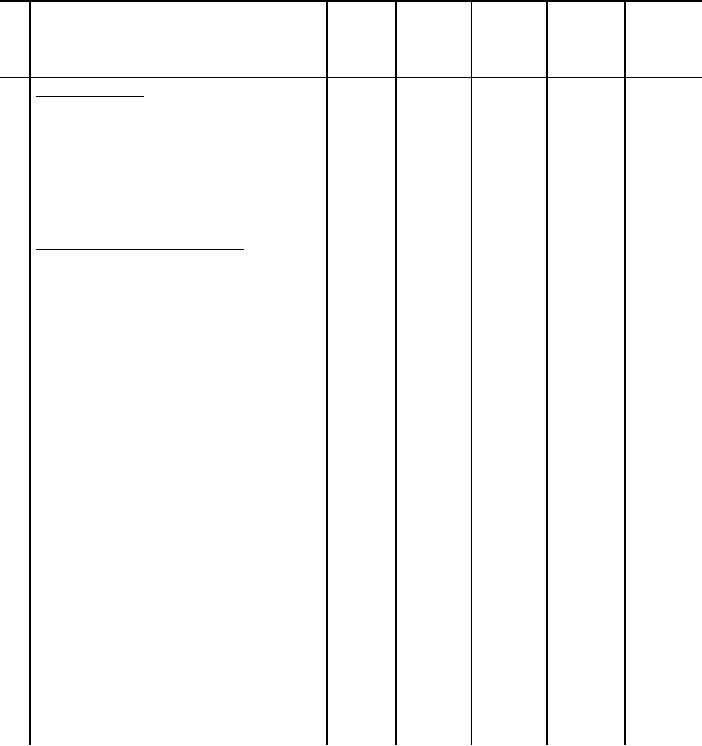

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

3 Blind facings. (cont'd)

3

a. Bind the raw back edge of the

301

BSb-1

10-14

A

A

facing with the 3/4 inch wide bias

cut binding, with the outside raw

edge only of the binding turned

under and caught in the stitching

1/16 inch from the inner folded

edge.

3 Seam lining to right vent.

4

Finished appearance. The vent

lining shall be uniformly stitched

and shall finish smooth and flat

without twists, gathers, puckers

or pleats.

a. Fold vent lining in half

301

SSa-1

10-14

A

A

lengthwise face to face and stitch

along the top, from the notches to

the folded edge, with a 5/16 to

3/8 inch seam. Turn vent lining

to the right side, forcing out

corner and seam.

b. Press vent lining smooth and

301

SSe-2

10-14

A

A

flat with a heated pressing iron

(a)

(silk)

(silk)

or pressing machine. Position the

raw edge of lining on the outside

of right vent, with notches on the

lining in line with the top end of

vent; then seam together 3/8 inch

from back edge. The lining shall

extend from the notches to the

bottom finished edge of coat.

c. Turn the lining to the inside

301

SSe-2

10-14

A

A

with seam 1/16 to 1/8 inch back of

(b)

(silk)

(silk)

folded edge. Stitch the entire

length of vent 1/8 inch from the

folded edge.

40

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business