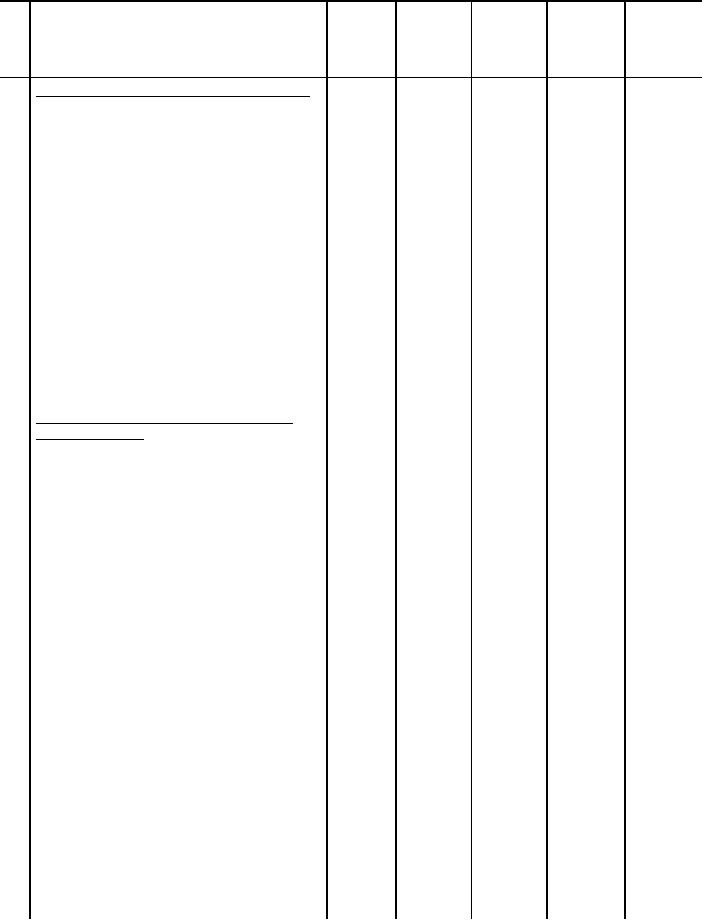

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

2

Assembly sleeve and sleeve lining.

4

(cont'd)

a. Position the sleeve lining on

the sleeve with the notch on the

lining even with the armhole edge

of sleeve and extending the same

width around the armhole edge of

sleeve.

b. Seam or tack lining to sleeve

301

SSa-1

6-8

A

A

backarm and forearm seam

or

(Commer-

(Commer

allowance, respectively,

Hand

cial)

-cial)

approximately 4 inches above

finished bottom edge of sleeve and

extending to approximately 6

inches below armhole edge at the

backarm and approximately 4-1/2

inches below armhole edge at the

forearm.

Fell turnup of sleeve lining:

2

5

press sleeves.

Finished appearance. The sleeve

linings shall not be short, tight

or twisted at bottom of sleeves,

and shall extend to within 1 to

1-1/4 inches from finished end of

sleeve. The sleeves shall be

properly pressed.

a. Pull sleeves through lining

101

(Commer-

and turn under the bottom edge of

or

cial)

sleeve lining to finish 1 to 1-1/4

Hand

inches above the finished end of

the cuff. The sleeve lining may

be felled to bottom of sleeve

without basting.

b. Fell the folded edge of sleeve

103

EFc-1

6-8

0

0

lining to turnup of the cuff with

(b)

(silk or

(silk

blind stitching.

or

nylon)

or

Hand

8-10

(silk or

nylon)

nylon)

(silk

or

nylon)

c. Turn sleeves and assembly in

pairs. The sleeves may be pressed

prior to setting. The backarm

crease shall be on the backarm

seam.

33

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business