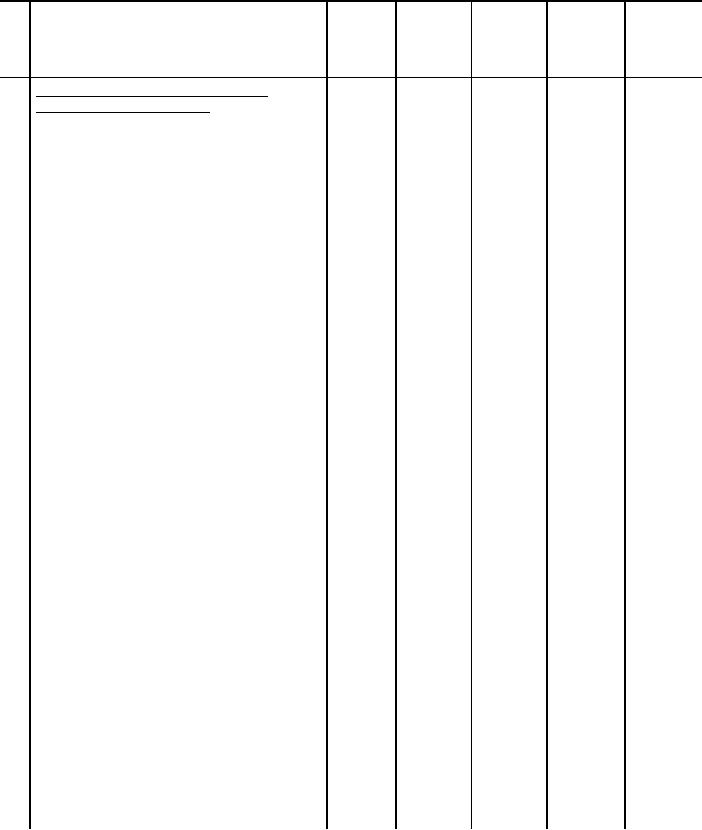

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

1

Make upper pockets (creasing

4

machine construction). (cont'd)

f. Turn under and crease the side

and bottom edges of the pockets in

a heated edge creasing machine.

Trim the lower corners of pockets.

-or-

g. Fold the pocket in half

301

OSf-1

10-14

A

A

lengthwise and stitch 1-1/2 inches

from the edge.

h. Form the pleat and seam across

301

SSa-1

10-14

A

A

the top and bottom edges,

respectively, 1/8 inch from raw

edge.

i. Press pleat in center of

pocket smooth and flat.

j. Trim the pocket to conform to

301

SSa-1

10-14

A

A

upper finished pocket shaper with

a 3/16 inch seam allowance added.

Sew the polyester/cotton twill

lining and pocket face to face,

after the pleat is formed and seam

around the sides and bottom 3/16

inch from the raw edges.

k. Turn the pocket so that the

101

Commerci

face side is on the outside and

or

al

baste edges with the twill lining

Hand

thread

slightly back from pocket edges.

Finished pocket must conform to

finished shaper.

l.

Stitch across top of pocket.

301

SSa-1

10-14

A

A

m. Bind the upper edge of the

301

BSc-1

10-14

A

A

pockets, including the lining,

with 7/8 inch wide bias binding,

with the pleat closed and outside

edge of the binding turned under

and caught in the stitching 1/16

inch from the inner folded edges

of the binding.

25

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business