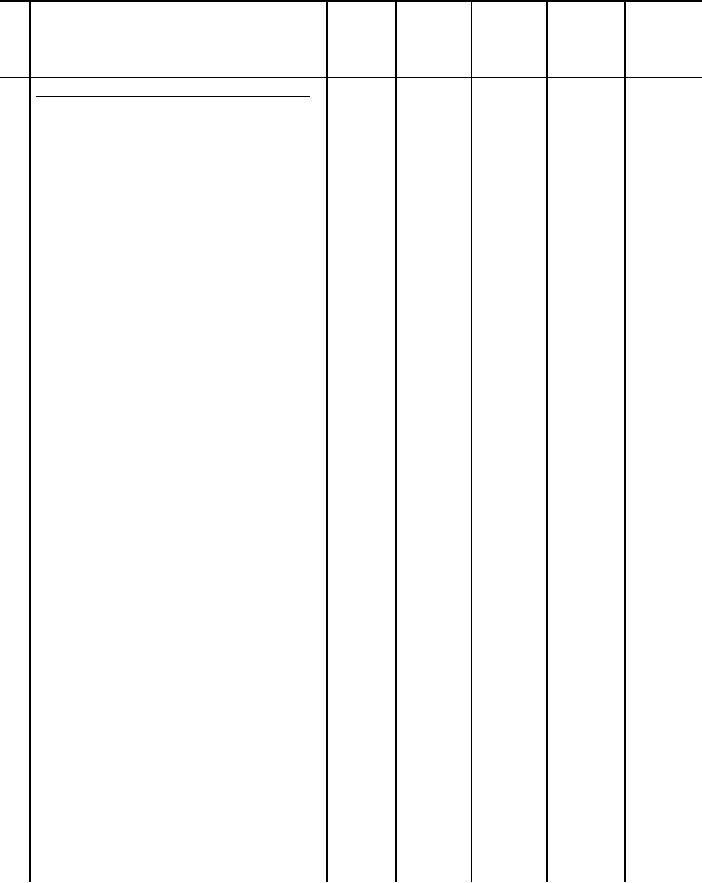

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

Make upper and lower pocket flaps.

1

3

(cont'd)

c. Turn the flaps, working the

301

SSe-2

10-14

A

A

edges, corners and point out

(b)

(silk)

(silk)

completely. Edgestitch the flaps

uniformly 1/8 inch from seamed

edges.

d. Mark and trim the top edge of

flaps with the finished shaper so

that in the finished coats, the

length of the flaps at center

point and sides shall conform to

measurements shown in Table III.

e. Overedge stitch together the

502

SSa-1

8-10

A

A

top raw edges of flaps.

or

503

SSa-1

8-10

A

A

f. Make a vertical, cut first,

Button

38 per

B

F

eyelet end, square bar type

-hole

(silk)

(silk)

buttonhole with a 3/4 inch long

button-

cut, through the center of each

hole

(not

breast patch flap with the edge of

incl.

the eyelet 5/8 inch above the

tack)

center point.

g. Make a vertical, cut first,

Button

38 per

B

F

eyelet end, square bar type

-hole

(silk)

(silk)

buttonhole with a 3/4 inch long

button-

cut through the center of each

hole

lower patch pocket flap with the

(not

inside edge of the eyelet 5/8 inch

incl.

above the center point of the

tack)

flap.

h. Securely bartack the ends of

Bartac

21 per

B

B

the buttonholes, catching the ends

k

bartack

(silk)

(silk)

of the gimp in the bartack. Trim

(min)

the ends of the gimp.

NOTE: Combination cut first

buttonhole and bartacking

automatic machine is authorized.

Care shall be exercised in

trimming excess gimp at end of

buttonhole.

i. Press upper and lower pocket

flaps smooth and flat.

23

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business