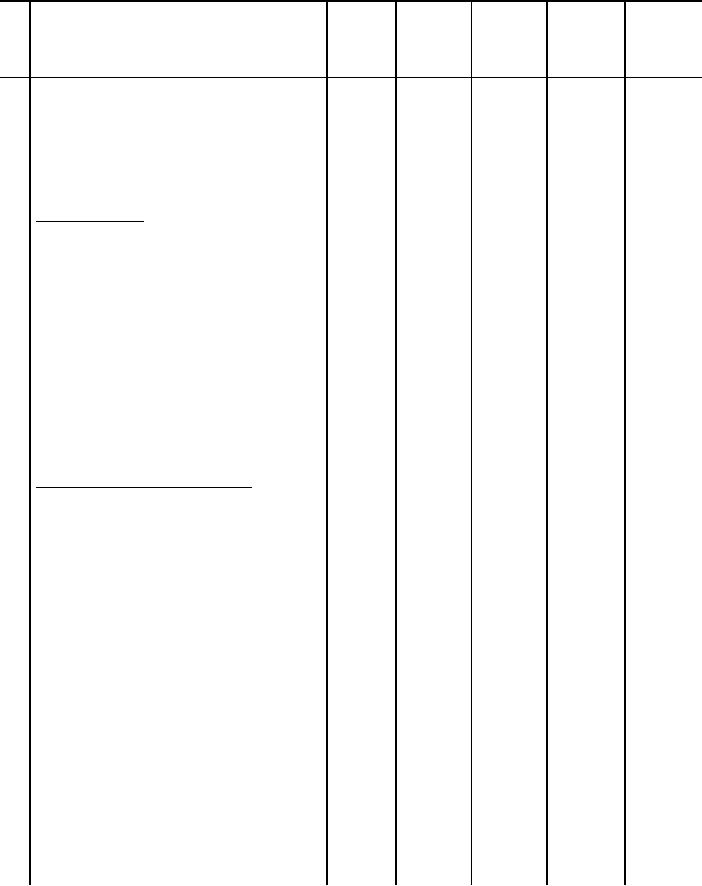

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

b. Replace any parts damaged

during the manufacturing process

by needle chews which may develop

into a hole, scissor or knife

cuts, tears, holes, mends or burns

in the material affecting

appearance.

Shade marking.

3

a. Mark or ticket (see 3.6.2) all

component parts cut from one piece

of basic material, and the two

parts of the under collar to

insure uniform shade and size

throughout the coat. All lining

parts shall be marked, bundled or

ticketed to insure uniform shade

and size throughout the garment.

b. The use of tickets with any

metal fastening devices or sew-on

shade tickets is prohibited on the

rayon lining.

4

Make belt loops and keeper.

Finished appearance. The belt

loops and keeper shall be

uniformly stitched, uniform in

width and shall finish smooth and

flat without pleats, gathers,

puckers or other distortion.

a. The belt loops and keeper

shall be made from a 1-inch wide

strip of basic material.

b. Fold the sides of the strip

406

EFb-1

10-14

A

A

lengthwise towards the center,

abutting the raw edges, and join

the raw edges together with a

covering stitch, to finish 1/2

inch wide. The stitching shall be

uniformly 1/8 inch from finished

edges of the loops and keeper.

c. Cut the loop for the left and

right sides of the coat 5-1/2

inches and 3-1/2 inches long,

respectively.

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business