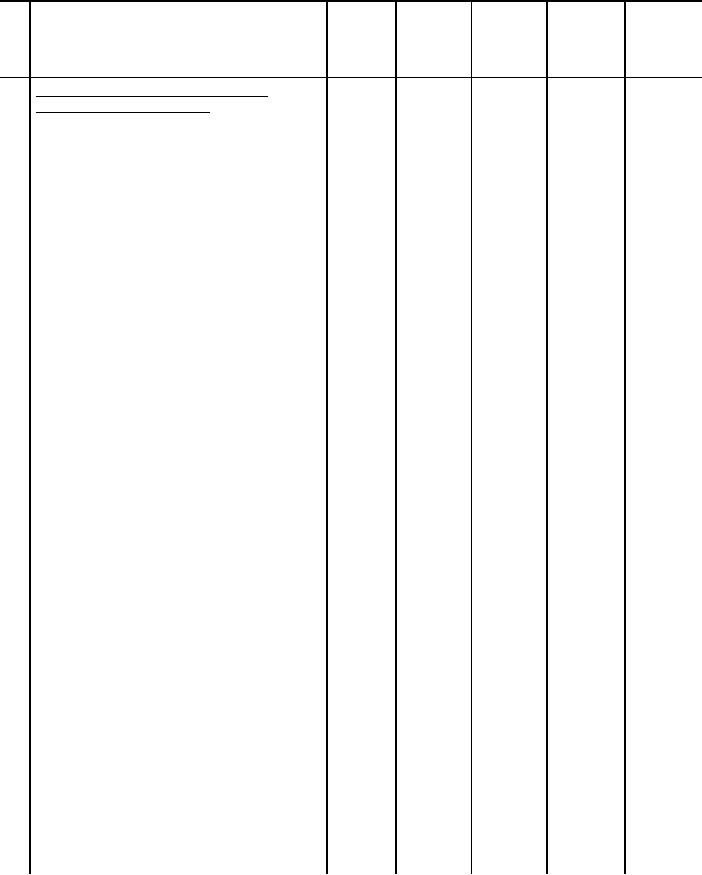

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

Make upper pockets (creasing

1

4

machine construction).

Finished appearance. The binding

shall be uniformly stitched; shall

not be tight or full causing

puckers, gathers, or pleats; and

the basic material shall be

securely caught in the stitching.

The pleats shall be vertically

centered and the folded side edges

of the pleats shall be parallel.

The pockets shall be uniform in

shape and size in accordance with

the pattern. The pockets shall be

lined with polyester/cotton cloth

twill and the pleats shall be

stitched.

a. Form a vertical box pleat on

the outside center of upper

pockets with a heated creasing

machine. The pleat shall be 1-1/2

inches wide.

b. Secure the pleat with a row of

301

SSa-1

10-14

A

A

stitches 1/8 inch from the top and

bottom edges, respectively.

c. Stitch the abutted edges of

103

SSm-1

4-8

A

A

the pleat together on the inside

of the pocket with blind

stitching.

d. Place the polyester and cotton

301

SSa-1

10-14

A

A

twill lining on the underside of

pocket after the pleat is formed

and stitched and seamed together

along the top, sides, and bottom

1/8 to 3/16 inch from the raw

edges.

e. Bind the upper edge of the

301

BSb-1

10-14

A

A

pockets, including the lining,

with 7/8 inch wide bias binding,

with the pleat closed and the

outside edge of the binding only

turned under and caught in the

stitching 1/16 inch from the inner

folded edges of the binding.

24

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business