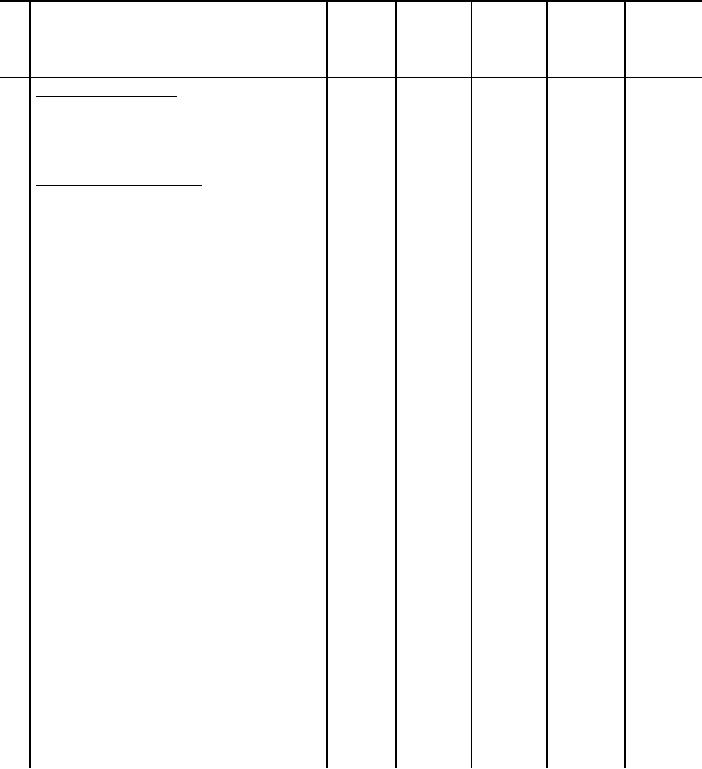

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

1 Make lower pocket. (cont'd)

5

h. The pockets shall be uniform

in shape and size in accordance

with the finished pocket shaper.

Make shoulder straps.

1

6

Finished appearance. The shoulder

strap shall be uniformly stitched

and shall finish smooth and flat,

without twists, gathers, puckers,

pleats, or raw edges. The

buttonholes shall be cut-first

type, well made, properly

positioned, well worked over gimp

to fit a 27-line insignia button,

and the stitching shall be

securely caught in the basic

material. The gimp shall be

pulled through to the underside of

the buttonhole, and purling of the

buttonholes shall be on the

outside of the shoulder straps.

a. The shoulder straps shall be

made of one ply of basic material

and one ply of interlining.

b. Fold side edges face to face

301

SSe-2

10-14

A

A

enclosing the interlining and seam

(a)

together with 1/4 inch seam.

c. Press seam open with a heated

iron.

d. Stitch pointed end of strap

301

SSe-2

10-14

A

A

with a 1/4 inch seam.

(a)

e. Trim points and turn the

301

SSe-2

10-14

A

A

straps, working the seams out to

(b)

the edges. Fold straps according

to notches and topstitch the strap

uniformly 1/8 inch from the edges.

27

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business