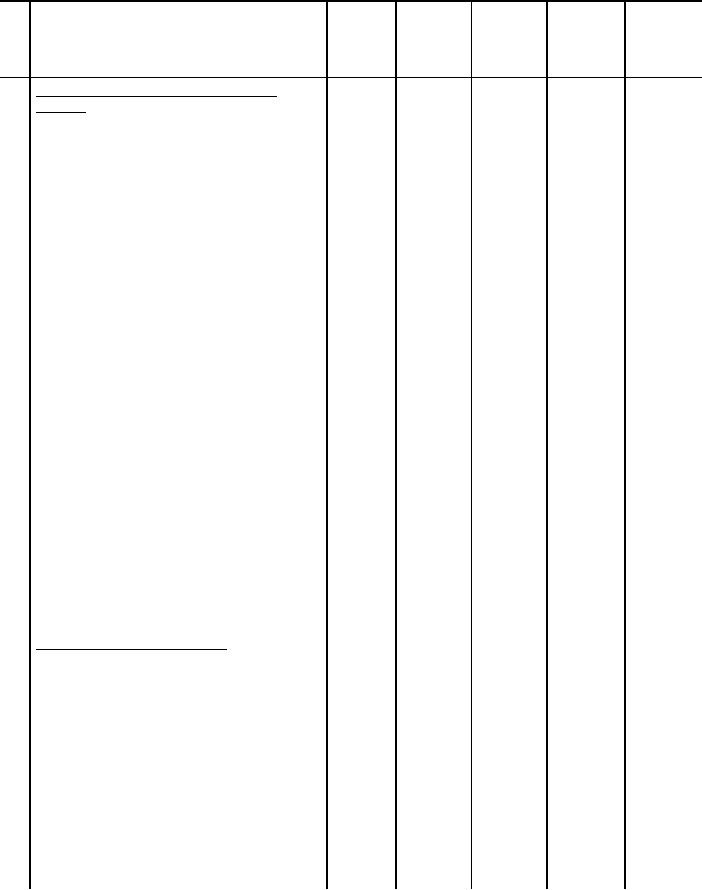

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

1 Assemble top collar and under

8 collar. (cont'd)

e. Baste the ends and upper edge

101

(Commer-

and along the breakline, with the

cial)

fullness placed between the two

rows of basting stitches.

f. If ends of collar are felled

Hand

8-10

C

by hand, 1/8 inch must be cut off

(silk)

the ends of the collar.

NOTE: When collar ends are hand

felled, the ends of under collar

will not be turned under.

g. Press the collar smooth and

flat with a heated pressing

machine. Edges and corners shall

be smooth, flat and uniformly

even.

h. Trim the lower edge of the top

collar to provide seam allowance

for seaming to the coat. Cut a

guide notch in the lower edge of

the top collar at the center.

i. Make one eyelet at each end of

Eyelet

20 per

A

A

the collar one inch from the side

eyelet

(silk)

(silk)

and upper edges, respectively.

(min)

The eyelets shall be well worked

with the purling on the outside of

the collar, and shall finish with

a 1/8 inch diameter opening.

1

Seam sleeves at forearm.

9

Finished appearance. The forearm

seam shall finish smooth and flat

without twists, gathers, puckers

or pleats and shall start and

finish evenly.

a. Position the top and under

301

SSa-1

10-14

A

A

sleeves with notches matching and

or

join at the forearm with a 3/8

401

SSa-1

10-14

A

A

inch seam.

b. Spread open the seam and press

flat with a heated pressing iron,

holding seam short.

30

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business