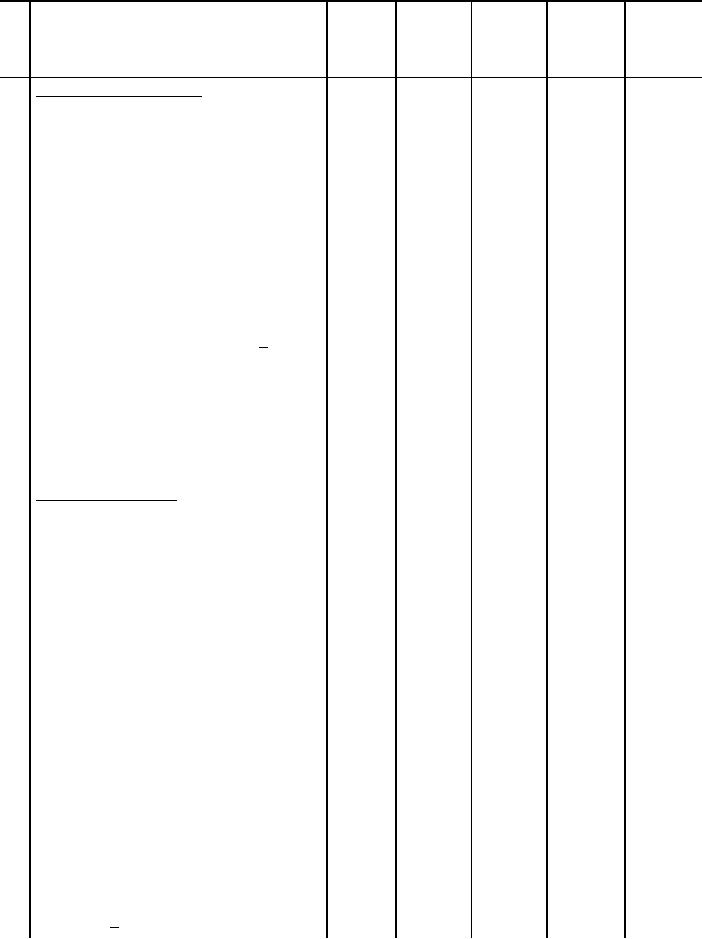

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

1 Make shoulder straps. (cont'd)

6

f. Make a horizontal eyelet-end,

Button

38 per

B

F

square bar type, cut first

-hole

(silk)

(silk)

buttonhole, 3/4 inch long, in each

button-

strap midway between the back and

hole

front edges, with the inside edge

(min

of the eyelet placed so that in

not

the finished coat, the edges of

incl.

the shoulder strap button will be

1/4 to 1/2 inch from the edge of

bartack

the collar. The purling shall

)

finish on the outside of the

strap.

g. On the finished coat, the

straps shall measure 2-3/8 + 1/8

inches at the eyelet end of the

buttonhole.

h. Press the straps smooth and

flat with a heated pressing iron

or pressing machine. The strap

shall be uniform in shape and size

in accordance with the pattern.

1

Make under collar.

7

a. The under collar assembly may

consist of one or two pieces of

under collar cloth and a single

piece of cotton buckram

interlining material, or the

interlining may be two pieces.

b. Join the two halves of the

301

SSa-1

10-14

A

A

under collar with a 3/8 inch seam

(when two-piece construction is

used).

c. Spread the seam open and press

flat with a heated pressing iron.

d. Join the two halves of the

301

LSa-1

10-14

A

A

interlining together with a 3/8

inch lap seam (when two-piece

construction is used).

e. Mark the breakline of under

collar with the under collar stand

marker.

f. Stitch under collar to inter-

301

SSa-1

10-14

A

A

lining at breakline; stand shall

be 1-1/4 + 1/8 inches at center.

28

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business