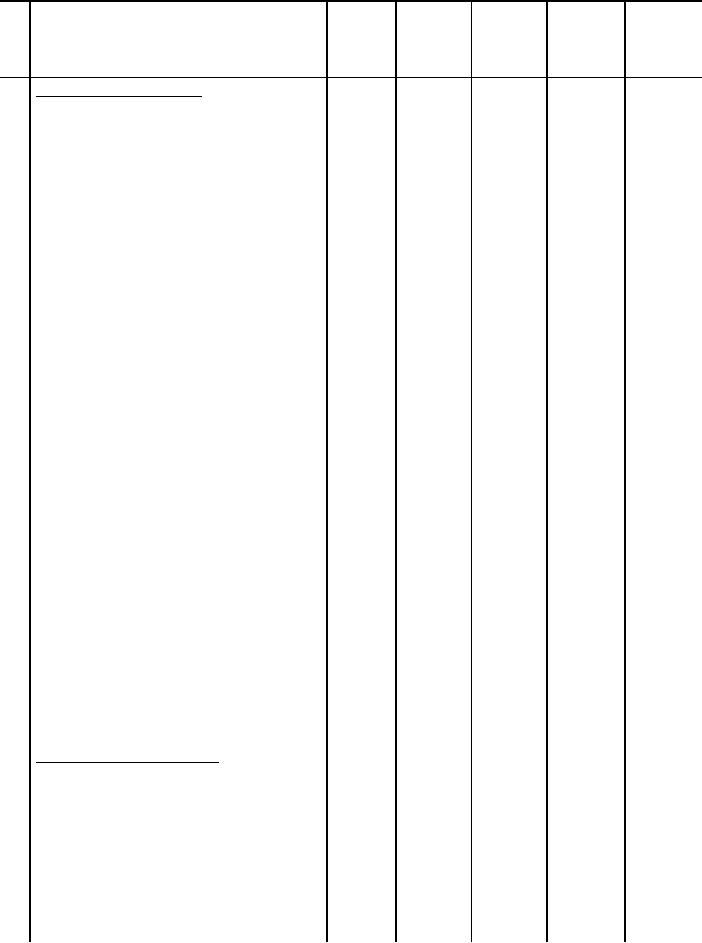

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

2

Join cuffs to sleeve.

0

Finished appearance. The upper

curved edge of cuffs shall be

properly formed and creased and

the cuffs shall be uniformly

stitched to sleeves. The point of

the cuff shall be centered between

the lower front creased edge and

the creased backarm seam of

sleeve.

a. Fold the cuff lengthwise at

301

SSa-1

10-14

A

A

the point with wrong side out.

Tack the point 1/8 inch from the

raw edges. Turn cuffs, completely

working out the point.

b. Turn under the upper edge of

the cuff, forming the finished

curved edge in accordance with the

shape of the pattern. Press

smooth and flat with a heated

pressing iron or pressing machine,

creasing the edge.

c. In lieu of pressing, the turn

101

(Commer-

under at upper edge of cuffs may

or

cial)

be basted.

Hand

d. Mark the sleeves in accordance

with the sleeve cuff marker for

positioning the cuffs, with notch

on the pattern matching the

forearm seam line and with the

lower edge of the sleeve and

marker even.

e. Position the cuffs at the mark

301

LSd-1

10-14

A

A

on the sleeve and seam uniformly

(silk)

(silk)

1/8 inch from the upper folded

edge of cuff.

2

Seam sleeve at backarm.

1

Finished appearance. The backarm

seam shall finish smooth and flat

without twists, gathers, puckers

or pleats and shall start and

finish evenly.

a. Join the top sleeve to the

301

SSa-1

10-14

A

A

under sleeve at the backarm with a

or

3/8 inch seam, catching the ends

401

SSa-1

10-14

A

A

of the cuff in the seam.

31

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business