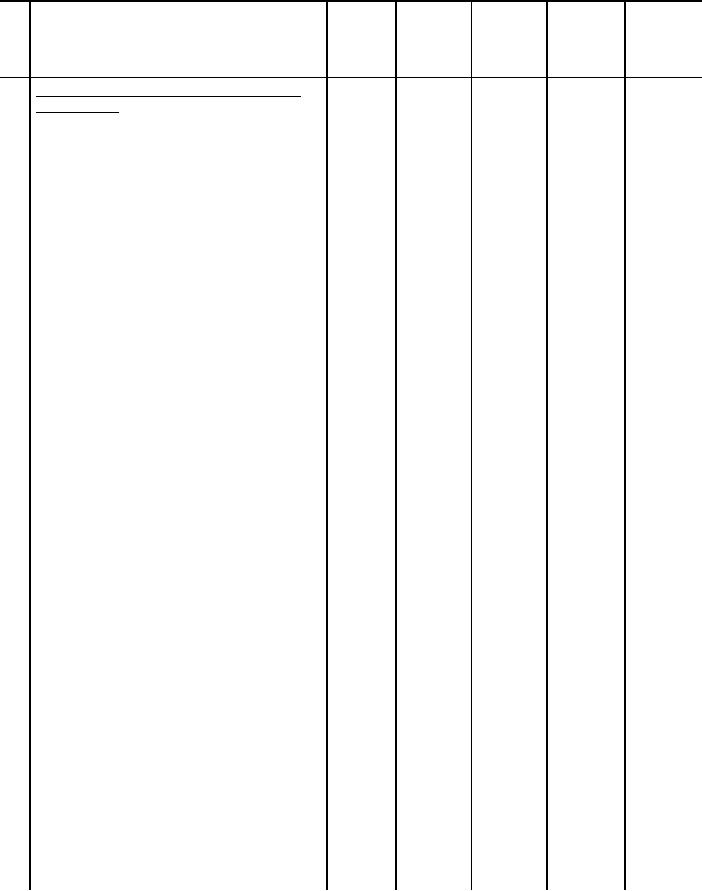

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

3 Assemble inside pocket on lining

1 and facing. (cont'd)

e. Position the pocket at the

mark with the pocket facing next

to the lining material. Place the

polyester/cotton twill stay piece

on the underside of the lining,

with the diagonal extension of the

stay extending to the armhole edge

of the lining.

f. Stitch the pocket to the

301

SSv-2

10-14

A

A

lining and facing through the stay

piece with one row of stitches

3/16 to 1/4 inch on each side of

the mark for the pocket opening.

g. Cut the opening for the pocket

midway between the two rows of

stitches joining the pocket and

pocket stay to the lining and

facing, tongue notching each end

of the opening.

h. Turn the pocket through the

301

BSp-2

10-14

A

A

opening to the inside with the

front and the backs of the pocket

toward the bottom and top edges,

respectively, of the lining. Form

the piping at the top and bottom

edge of the opening. Topstitch

the upper and lower edges of the

pocket opening adjacent to the

seamed outer edge of the piping.

-or-

i. Accomplish the pocket opening

101

A

A

with a double piped pocket machine

or

A

A

which stitches, cuts and turns in

301

one operation. When this machine

is used, the piping piece may be

trimmed to permit insertion into

the machine. The joining seam of

the top and bottom piped edges

shall be raise stitched through

lining and coat facing prior to

pocket closing and top edge

stitched through all plies. Tack

ends of pocket opening.

37

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business