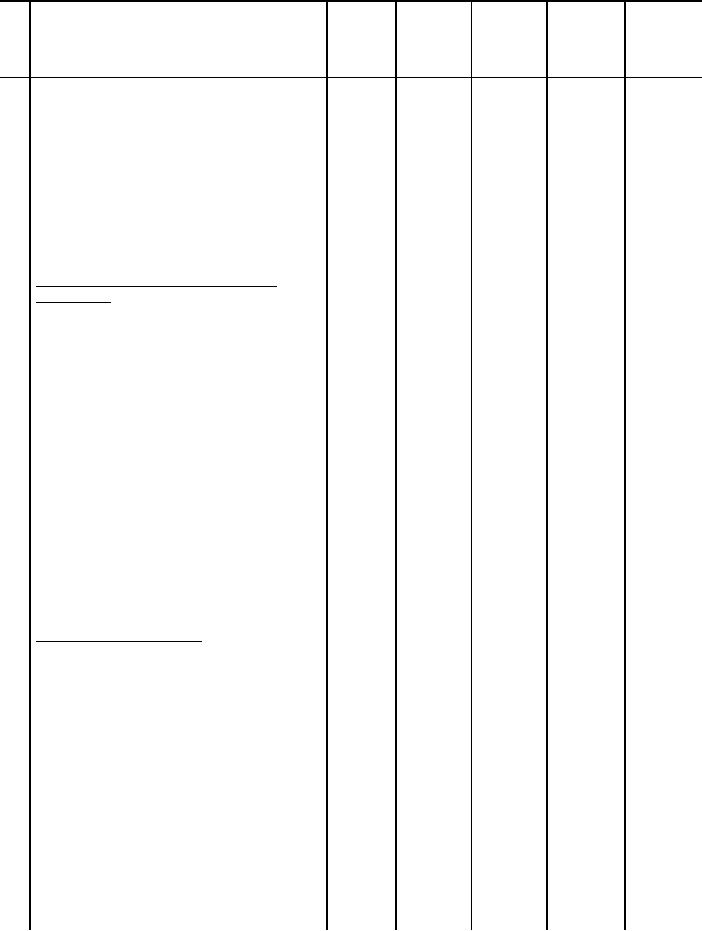

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

b. Securely sew one button at

101

21 per

20/4

each mark. The button for the

buckle end shall properly engage

button-

buttonhole in buckle end and shall

or

hole

be sewn through all plies of

Hand

(min)

material so that the edge of turn

3-4

back will not show when button is

(double

engaged with buttonhole. The

thread)

button for the belt fastener shall

be sewn through the underside and

interlining only.

Bartack fastener to belt (see

1

0

Figure 5).

Finished appearance. The belt

fastener shall be smooth and flat

without twisting or bulging when

buttoned. The bartack shall

extend across the entire width of

the fastener and the stitch shall

be formed with balanced thread

tension.

a. Mark the underside of the belt

in accordance with the mark on

pattern for each size belt, for

the location of belt fastener.

b. Turn under the raw end of the

Bartac

28 per

A

A

fastener 1/2 inch and bartack the

k

bartack

(silk)

(silk)

fastener to the belt through all

(min)

plies 1/8 to 3/16 inch from the

folded edge.

1

Clean and press belt.

1

Finished appearance. The belt and

belt keeper shall be clean and

well pressed with the keeper

attached and secured to the belt.

a. Trim all ends of stitching and

remove all loose ends of thread

from the belt. Remove all spots

and stains from the belt without

injury to the material.

b. Place the keeper on the belt

at the square end and secure by

buttoning the end. Press the belt

and keeper smooth and flat with a

heated pressing iron or pressing

machine.

20

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business