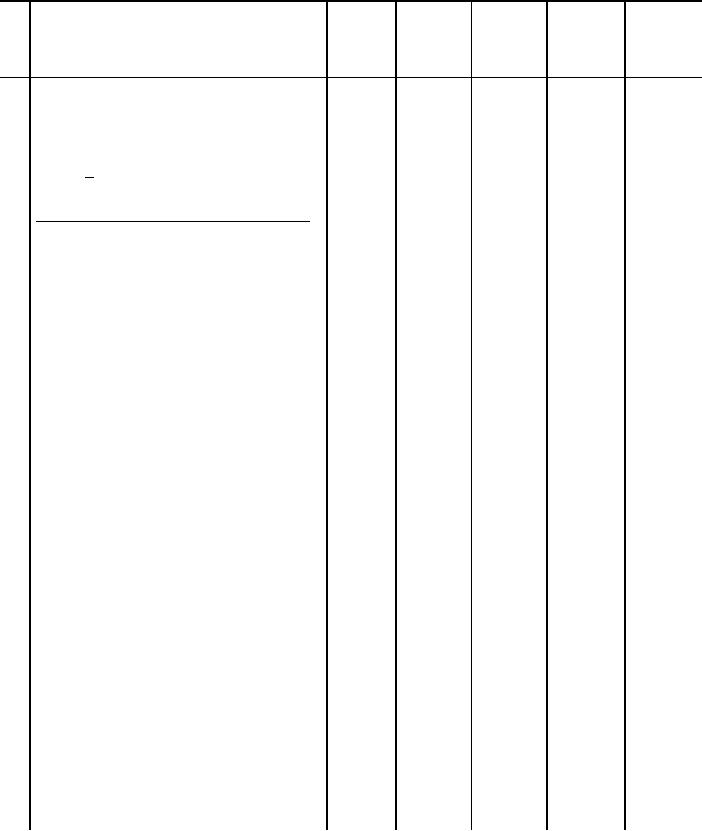

MIL-DTL-21083E(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

BOB/LPR

O

d. Cut the keeper 4-1/2 inches

Bartac

28 per

A

A

long, fold in half end to end, and

k

bartack

join the ends with a bartack

(min)

across the width of the keeper.

The finished keeper shall measure

2-1/8 + 1/8 inches from bartack to

folded edge.

5

Make belt fastener (see Figure 5).

Finished appearance. The belt

fastener shall be uniformly

stitched, uniform in width and

shall finish smooth and flat and

without pleats, gathers, puckers

or other distortion. The

buttonhole shall be clean cut,

well made and correctly

positioned. The buttonhole shall

be the straight type and shall be

made to fit a 22-line sewing hole

button. The purling of the

buttonhole shall be on the outside

of the fastener and ends of the

buttonhole shall be securely

tacked.

a. The belt fastener shall be

made from 1-5/8 inch-wide strip of

rayon lining material.

b. Fold the strip in half

301

EFp-2

10-14

A

A

lengthwise, turn in raw edges, and

(silk)

(silk)

stitch 1/8 inch from each side,

catching the turned edges in the

stitching, to form a 1/2 to 5/8

inch wide band. Cut the fastener

6-1/2 inches long.

c. Turn under one end of fastener

Button

42-48

A

A

1-1/2 inches and make a horizontal

-hole

per

straight type buttonhole, cut 5/8

inch long, through all plies in

button-

the center of the turned under

hole

portion, securely tacking each end

(min

of buttonhole.

(incl.

tack)

17

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business