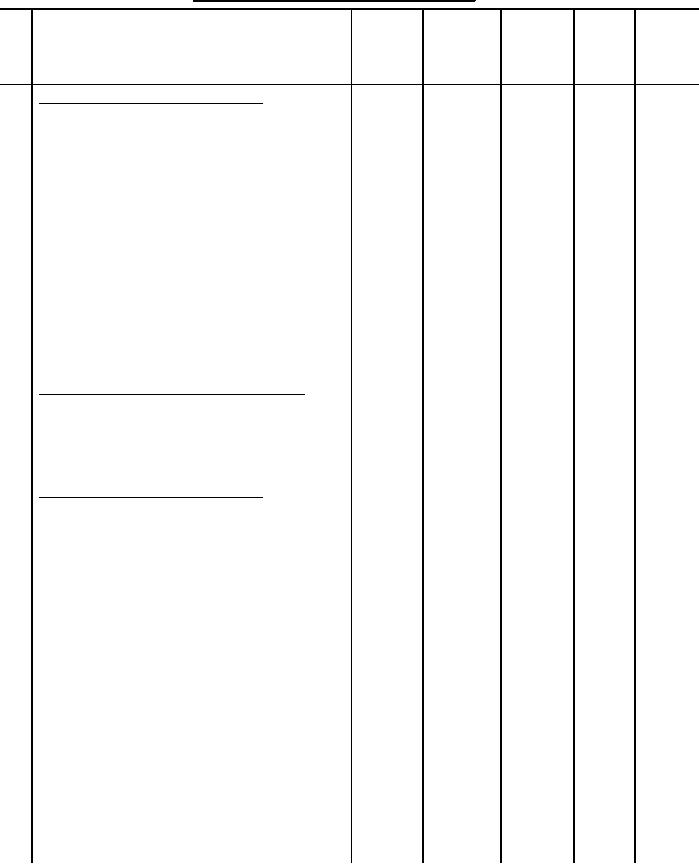

MIL-DTL-29389B(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

O

9

Set welt and hanging pocket.

(cont'd)

h. Close the pocket along the sides

301

SSa-1

10-14

A

A

and bottom, tacking the ends of the

pocket opening, and catching the

tongue notches in the stitching.

The row of stitches at the sides

shall be in line with the ends of

the pocket opening. The row of

stitches at the bottom of the pocket

shall be 3/8 to 1/2 inch from the

raw edge.

i. Tack the ends of the welt to the

301

SSa-1

10-14

A

A

front through the interlining. The

stitching shall be adjacent to the

edge stitching for the welt.

1

Dress left front and left facing.

0

a. Dress left front and facing from

top edge to lower end for eyelet

stand as indicated by marks on

pattern.

1

Stitch bridle tape to lapel.

1

Finished appearance. The bridle

tape shall be stitched along the

breakline with the proper tensions

to allow the lapel to roll properly

in the finished vest.

a. Position the 1/4 inch wide

bridle tape on the interlining side

of the fronts along the breakline of

the lapel and with the front edge of

the tape in line with the breakline.

The tape shall extend from the gorge

to approximately 1 inch above the

lower edge of lapel.

b. Stitch the tape through the

301

SSau-2

10-14

A

A

front of the vest evenly, smoothly

and with normal tension, holding the

tapes taut and working in 1/2 to 5/8

inch fullness along the breakline.

The tape shall be stitched 1/16 inch

from each edge.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business