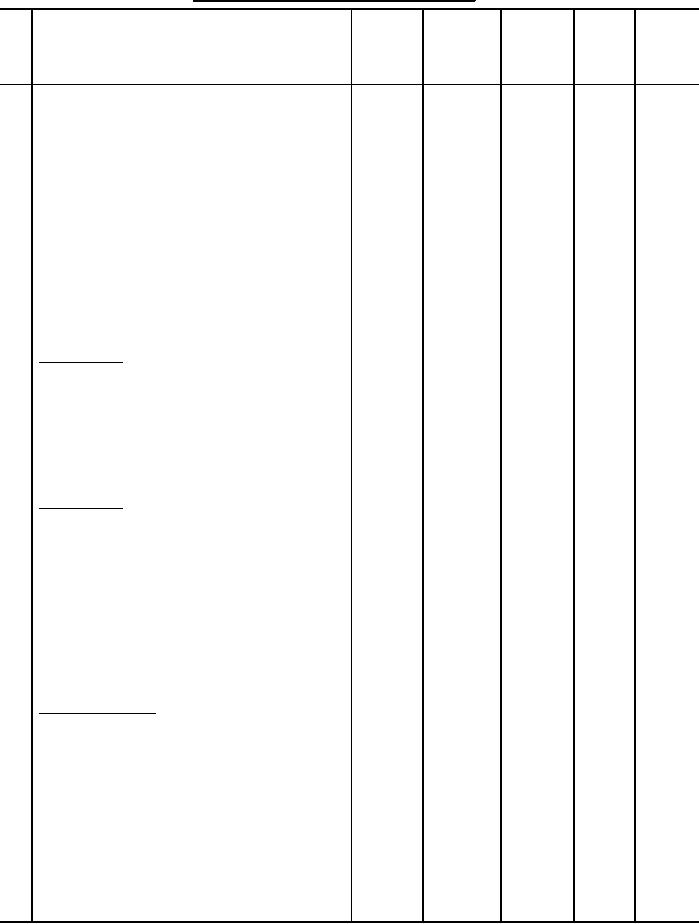

MIL-DTL-29389B(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

N

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

O

b. Make a horizontal, eyelet-end,

Button-

60 per

A

A

square-bar type buttonhole, cut 5/8

hole

(silk

(silk

inch, at each of the marks on the

button-

)

)

hole

left front. The inside edge of the

buttonhole eyelet shall finish 3/8

(min)

to 1/2 inch from the front edge.

c. The buttonholes shall be well

worked over gimp to fit the 22-line

button. The gimp shall be pulled

through to the underside. The

purling shall be on the outside.

d. Securely bartack the end of each

Bartack

21 per

40/3

40/3

buttonhole and trim the ends of the

bartack

gimp.

(min)

2

Clean vest.

4

a. Trim all ends of stitchings and

remove all loose threads from the

vest.

b. Remove all spots, shade tickets,

markers and stains from the vest

without injury to the material.

2

Press vest.

5

Finished appearance. Pressing shall

be done with a heated pressing iron

or pressing machine of a type

suitable to obtain the desired shape

and appearance in accordance with

good manufacturing practice.

a. Press the entire vest, removing

all wrinkles.

b.

Finish press the lining.

2

Attach buttons.

6

Finished appearance. The buttons

shall be properly attached to the

vest. The buttons shall be properly

aligned with the buttonholes to

secure a smooth and complete closure

without bulging or misalignment.

a. Attach four 22-line insignia

buttons to the right front with

shank of buttons inserted through

eyelets and secured by ring

fasteners.

20

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business