MIL-DTL-28920C(MC)

Manufacturing requirements - Continued.

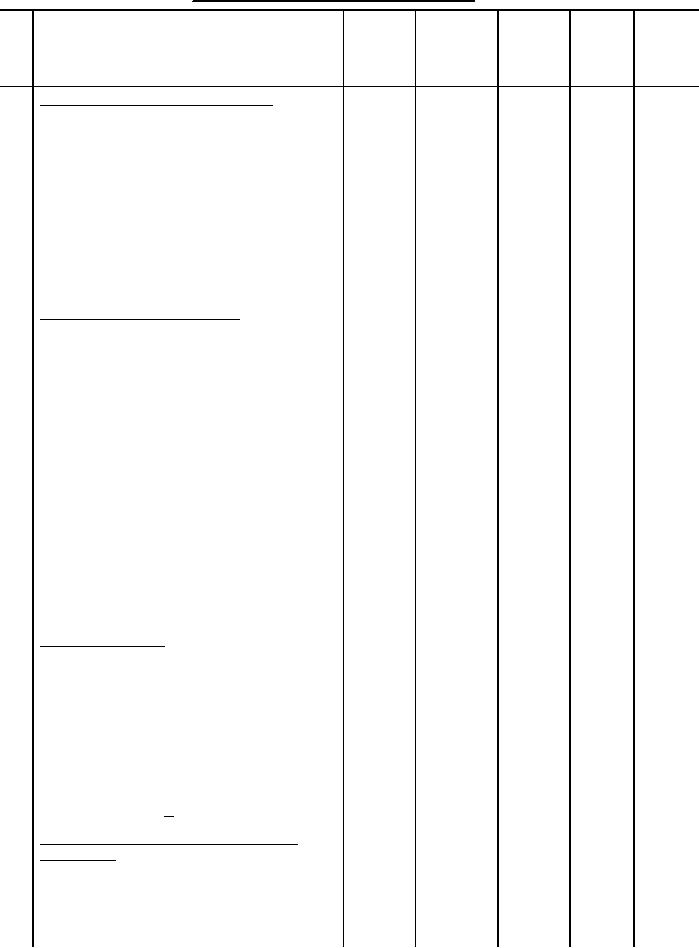

TABLE I.

SEAM

STCH

/

BOB/

NO

OPERATION

TYPE

STCH

STCH/I

NDL

LPR

TYPE

N

27

Seam front ends of waistband.

a. Turn back right fly lining and

301

SSe-2

12-16

A

A

stitch top end to front and top

(a)

edges of waistband, down to the

(each

buttonhole tab, rounding off the

edge)

corner slightly. Trim the corner.

b. Turn back the end of the left

301

SSa-1

12-16

A

A

waistband in line with the joining

seam of the left fly to front and

stitch across top edge of waistband

the width of the fly.

Join lining to waistband.

28

a. Insert top edge of waistband

304

12-16

40/3

40/3

between lining and buckram of

or

waistband lining, with edge of

404

12-16

40/3

40/3

lining turned in, and join all

or

plies with a row of imitation

Hand

7-10

40/3

handfelled stitches, or trouser

waistband lining may be felled by

hand.

b. Left end of waistband lining

shall finish at front edge of

trousers, with the end of the

waistband lining trimmed slightly

back from front edge on an angle.

Right end of waistband lining shall

extend approximately 1 inch under

the fly lining in the finished

trouser.

29

Press waistband.

a. Turn out front end of left and

right waistband, forcing out the

corners. Turn waistband lining to

inside and press along the top edge

of waistband. Trouser waistband

lining shall not be exposed beyond

top edge of waistband.

b. Finished width of waistband

shall be 1-3/4 + 1/8 inches.

30

Stitch pockets to lower edge of

waistband.

Stitch top end of all pockets to

301

SSa-1

6-10

A

40/3

waistband seam allowance with

pockets properly positioned and

smoothed out.

26

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business