MIL-DTL-28920C(MC)

Manufacturing requirements - Continued.

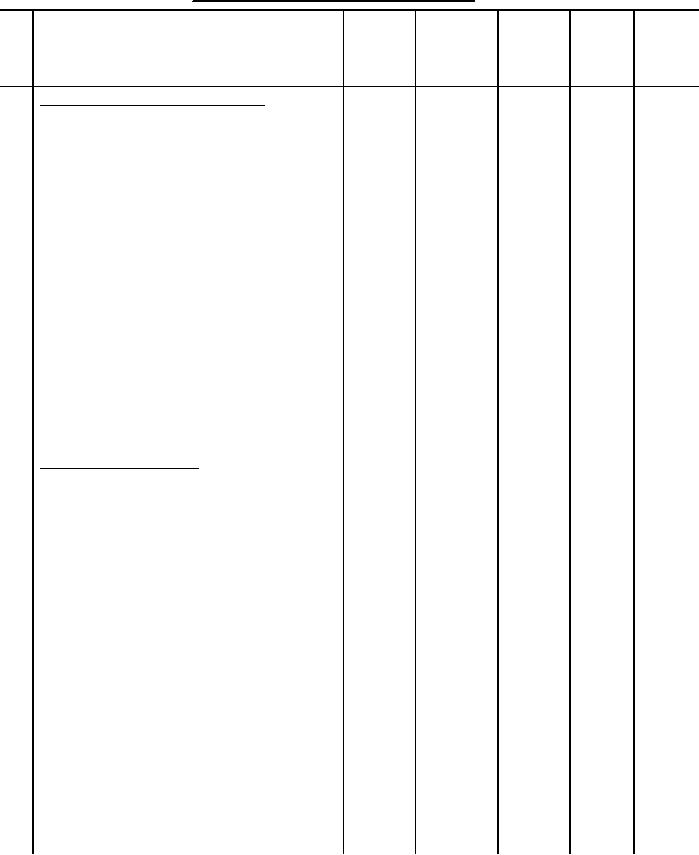

TABLE I.

SEAM

STCH

/

BOB/

NO

OPERATION

TYPE

STCH

STCH/I

NDL

LPR

TYPE

N

20

Join fly assembly to fronts.

Finished appearance. The seam

joining the fly assembly to the

fronts shall be without pleats,

puckers, twists, or other

distortions.

a. Sew on left fly with 3/8 inch

301

SSa-1

12-16

A

A

seam with notches matching.

b. Turn left fly to the inside

with joining seam 1/8 inch back of

folded edge and press front edge

without damage to the fastener.

c. Sew on right fly with 3/8 inch

301

LSq-2

12-16

A

A

seam with notches matching.

(a)

d. Press right fly seam open and

flat with heated pressing iron with

the fastener tape facing towards

side seam.

21

Attach side pockets.

Finished appearance. The edge of

the pocket openings shall finish

smooth and flat without distortion.

Pocket openings shall be of uniform

appearance. The bottom front

corners of the pockets shall be

backstitched, and care shall be

taken to avoid notching the pocket

on the underside beyond the width

of the side seam outlet.

a. Position the outside of the

fronts on the facing of the side

pocket in accordance with the

notches for the pocket opening as

indicated by marks on the pattern.

b. Seam the front, facing, and

301

SSe-2

12-16

A

A

pocket material together from notch

to notch 3/8 inch from the edge of

the front, with cotton stay tape

for edge of pocket opening caught

in the stitching.

22

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business