MIL-DTL-28920C(MC)

Manufacturing requirements - Continued.

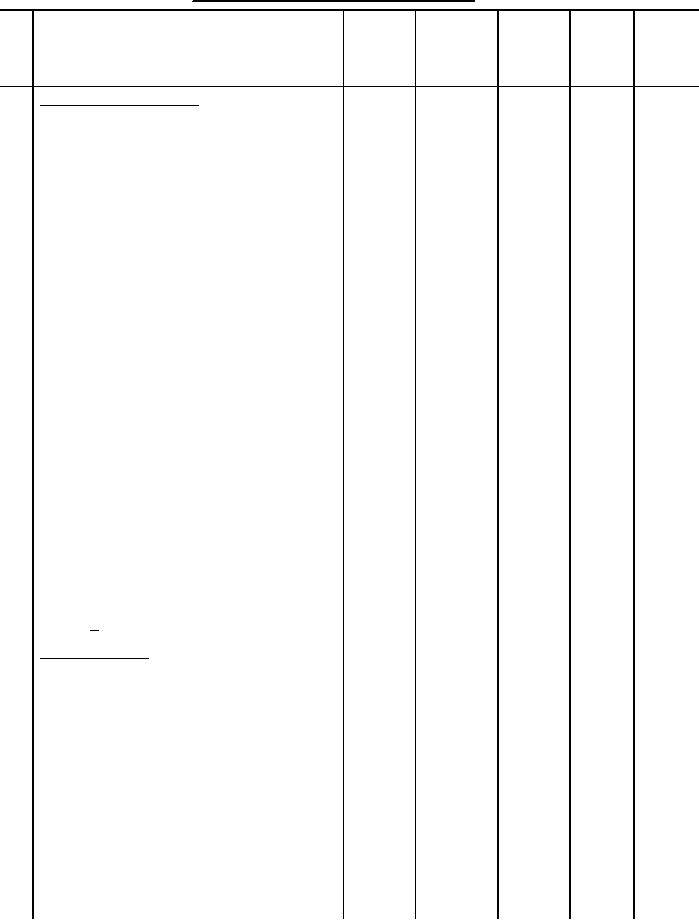

TABLE I.

SEAM

STCH

/

BOB/

NO

OPERATION

TYPE

STCH

STCH/I

NDL

LPR

TYPE

N

21

(cont'd)

Attach side pockets.

c. Cut the depth of the notches

for the pocket opening to the seam

and turn the pocket to the inside

of the front so that the seam will

finish on the inside of the pocket

1/8 inch back from the finished

edge of the pocket opening.

d. Topstitch the front from notch

301

SSe-2

12-16

A

A

to notch, through all plies of

(b)

(silk

(silk

material, 1/4 inch from the

(show

)

)

finished edge of the pocket

finished

opening.

seam)

e. Fold pocket inside out and seam

301

SSae-2

12-16

50/3

50/3

raw edges from step of pocket, 3/16

(a)

to 1/4 inch from edge, to bottom

or

and continue along the bottom of

401

SSae-2

12-16

50/3

50/3

pocket. Notch pockets and bearers

(b)

or

at top of step and turn.

70/2

f. Tack the ends of pocket opening

301

SSa-1

12-16

50/3

50/3

through facing with 1/4 to 3/8 inch

(each

tack.

end)

g. In the finished trousers, the

top of pocket shall extend into the

waistband and be caught in the

bottom stitching of waistband.

h. The finished pocket opening

(after bartacking) shall measure

6-1/4 + 1/4 inches.

22

Join outseams.

Finished appearance. Outseams

shall be carefully joined, with

notches matching, and without

twists, puckers, or pleats. The

seams shall start and finish evenly

and lie smooth and flat.

a. Join the outseam with a 3/8

301

SSav-2

12-16

A

A

inch seam, matching the notches as

or

(b)

indicated by marks on the patterns,

401

joining the back to the pocket

bearer and to the front at the side

seam and catching the side pocket

stay with its bottom edge turned

in.

23

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business