MIL-DTL-28920C(MC)

Manufacturing requirements - Continued.

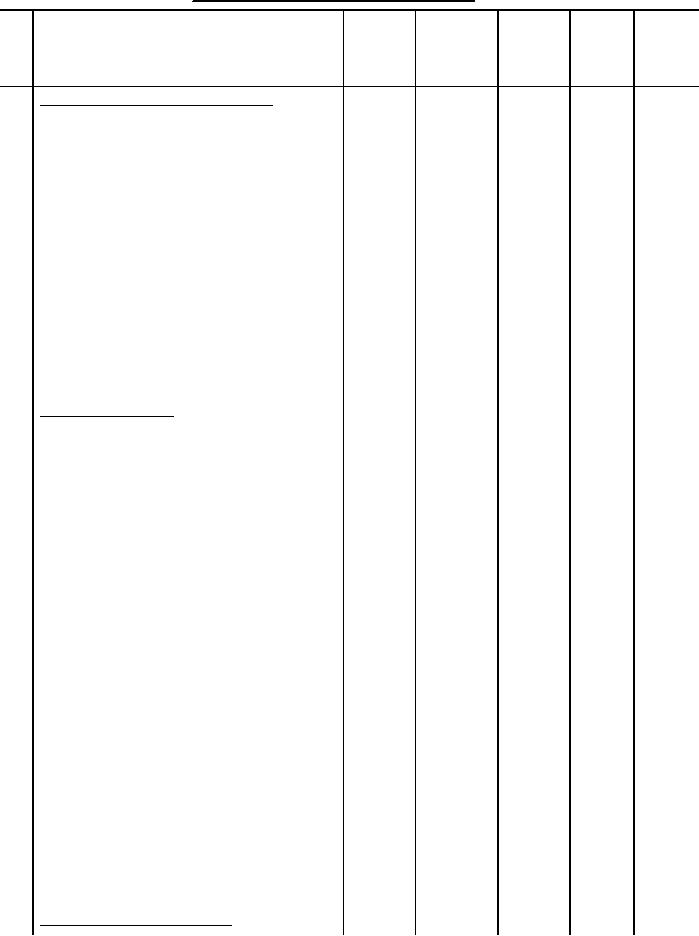

TABLE I.

SEAM

STCH

/

BOB/

NO

OPERATION

TYPE

STCH

STCH/I

NDL

LPR

TYPE

N

40

Make buttonhole in waistband.

Finished appearance. Buttonhole

shall be clean cut, well made, and

correctly positioned. The

stitching shall be securely caught

in the fabric.

a. Make a horizontal eyelet-end,

Button

48 min

A

A

taperbar type button hole cut 5/8

- hole

per

(silk

(silk

inch long through the left front

)

)

end of the waistband with the edge

button

of the eyelet 1/2 inch from the

-hole

front edge of the fly opening. The

(incl.

buttonhole shall be made in the

tack)

center of the waistband and shall

be worked over gimp to fit a

22-line button. The purling of the

buttonhole shall be on the outside.

Bartack trousers.

41

Finished appearance. The trousers

shall not be distorted by the

bartacks. The pockets shall lie

smooth and flat. The bartacks

shall be properly positioned and

correctly placed to reinforce the

points of strain as specified.

a. Bartack both ends of all pocket

Bartac

28 per

A

40/3

openings. Bartacks for the back

k

(silk

(silk

pockets and watch pocket shall be

bartac

)

)

vertical. Bartacks for the side

k

pockets shall be horizontal.

b. Bartack the bottom end of the

Bartac

28 per

A

40/3

fly horizontally through all plies

k

(silk

(silk

at the juncture of the crotch seam

bartac

)

)

and fly.

k

c. Bartack front edge of right fly

Bartac

28 per

0

40/3

to back of left fly with a vertical

k

bartack, with lower end of bartack

bartac

approximately 3/4 inch above the

k

horizontal bartacks at base of fly.

d. Bartacks shall be made 3/8 to

1/2 inch long, and shall be

stitched through all plies of

material at the point of

bartacking.

42

Sew buttons to trousers.

31

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business