MIL-DTL-28920C(MC)

Manufacturing requirements - Continued.

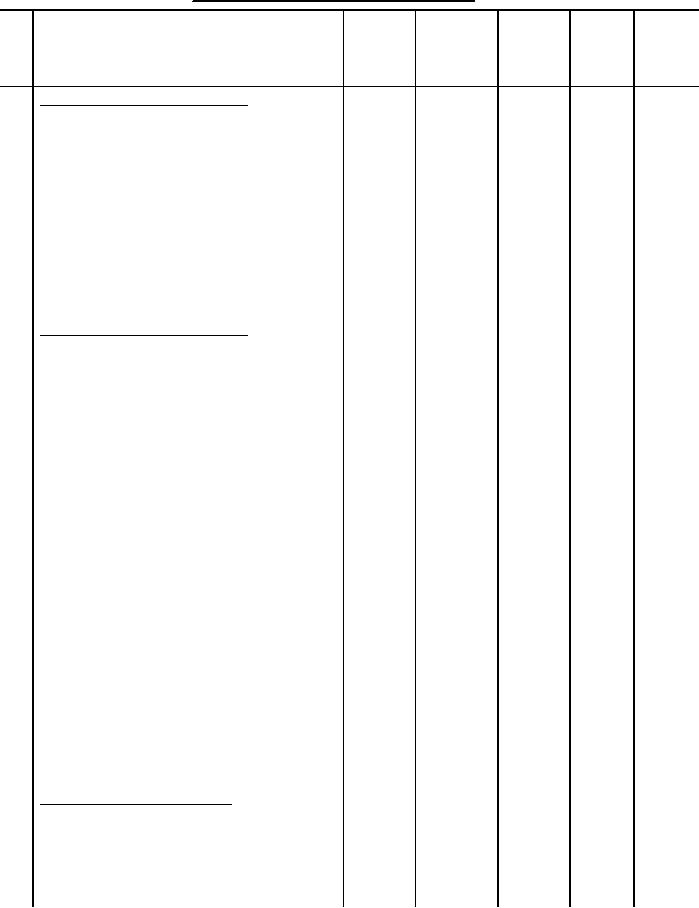

TABLE I.

SEAM

STCH

/

BOB/

NO

OPERATION

TYPE

STCH

STCH/I

NDL

LPR

TYPE

N

Join crotch and seat seam.

34

Finished appearance. The crotch

and seat seams shall be joined with

proper tension, resulting in

sufficient elasticity of seam to

counteract strain encountered in

sitting or stooping. In the

joining of the seat seam, the

inseams shall meet.

a. Measure waist to proper size

before joining crotch, seat, and

waist seam.

Join crotch and seat seam. (cont'd)

34

b. Place the left and right

assemblies together with the edges

of the crotch seam aligned with the

waistband on the left assembly,

aligned with the waistband on the

right assembly at the fly opening,

and with the notches at the lower

end of the flies matching.

c. Join the left and right

401

SSa-2

10-14

A

A

assemblies at the crotch and seat

seam from the fly notch to a point

1/2 to 3/4 inch from the top of the

finished waistband with two rows of

stitches not more than 1/32 inch

apart, forming a 1/2 inch V-shaped

opening at back. The left and

right assemblies shall be joined at

the crotch with a 1/2 inch seam.

d. Fold back waistband lining over

301

SSa-1

12-16

A

A

the joining seat seam and single

(each

stitch each end of the outlet 1/4

end)

inch from seat seam, with the lower

corner diagonally folded and caught

in the stitching. Turn and force

out upper corners.

35

Assemble slide fastener.

a. Attach slider and securely

staple bottom of fastener together

with the ends of the chain even and

the head of the staple towards the

outside.

28

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business