MIL-DTL-28920C(MC)

Manufacturing requirements - Continued.

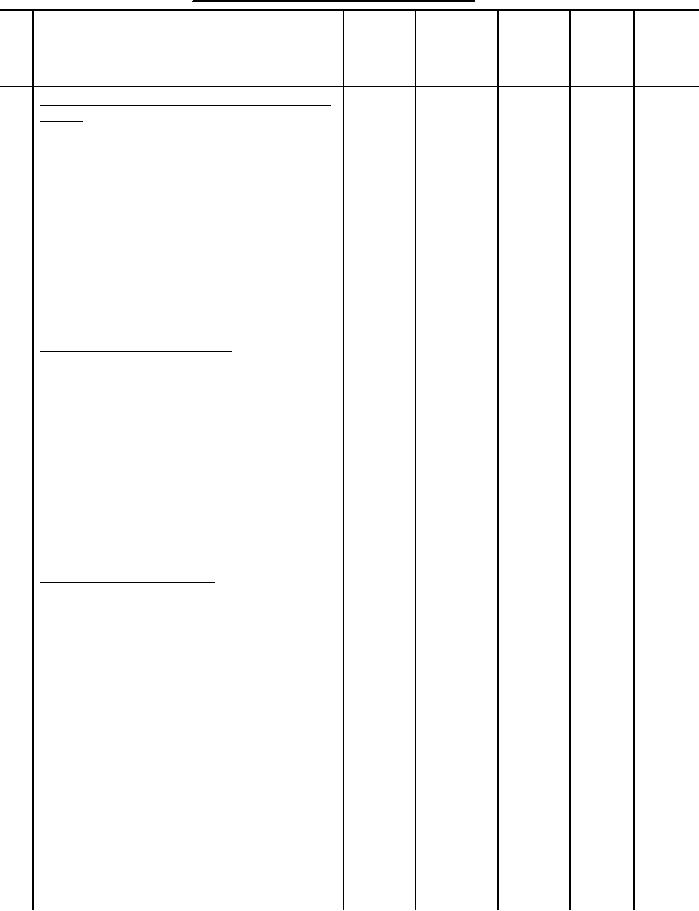

TABLE I.

SEAM

STCH

/

BOB/

NO

OPERATION

TYPE

STCH

STCH/I

NDL

LPR

TYPE

N

Make watch pocket (style A trousers

13

only). (cont'd)

c. Properly position front and

301

SSe-2

12-16

40/3

40/3

back pieces of the pocket with

(a)

edges even and join together at the

side and bottom edges with a 1/4

inch seam. The stitching shall

extend from notch to notch at upper

side edges.

d. Turn the pocket, forcing out

301

SSe-2

12-16

40/3

40/3

the seamed edges. Topstitch the

(b)

pocket uniformly 1/4 inch from the

seamed edges.

Make ornamental stripes.

14

Finished appearance. The scarlet

stripes shall be basted without

distortions and the finished stripe

shall be uniformly 2 inches wide

for type I trousers and 1-1/2

inches wide for type III trousers.

a. Fold the raw edges of the

101

4-6

stripes so that they abut each

other at the center back of the

finished stripes and baste along

the folded edges.

15

Make waistband lining.

Finished appearance. The waistband

lining shall be without distortion.

a. The waistband lining shall be

made of one ply of lining material

and one ply of buckram.

b. Overlap lining material on

301

LSa-1

6-10

40/3

40/3

buckram 3/4 inch and stitch 1/8 to

or

3/16 inch from edge of lining

401

material. Fold lining material

over buckram and press.

- or -

c. Use a commercial, buckram

interlined, waistband lining,

provided the furnished lining

conforms to specification

requirements.

17

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business