MIL-DTL-28920C(MC)

Manufacturing requirements - Continued.

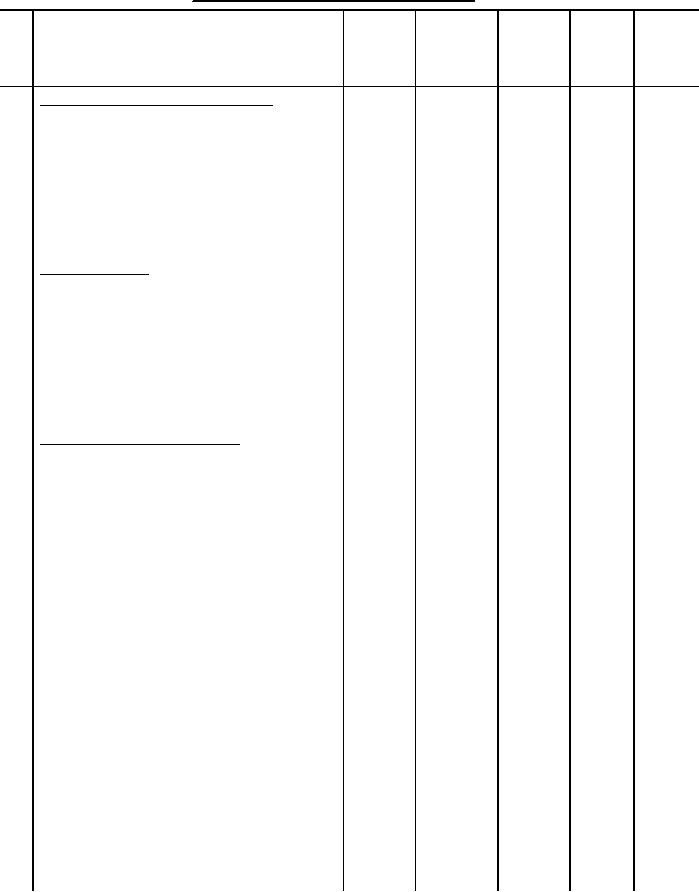

TABLE I.

SEAM

STCH

/

BOB/

NO

OPERATION

TYPE

STCH

STCH/I

NDL

LPR

TYPE

N

Replacement of damaged parts.

2

(cont'd)

b. Replace any part damaged during

the manufacturing process by needle

chews which may be expected to

develop into a hole, scissors or

knife cuts, tears, holes, mends,

burns, and large exposed drill

holes.

Shade marking.

3

a. Mark or ticket the component

parts to ensure a uniform shade and

proper assembly throughout the

trousers, except those parts

specified in operation 1.c, which

may be cut from ends and need not

match each other. Ticket shall

conform to 3.6.2.

4

Overedge stitch trousers.

Finished appearance. The overedge

stitching shall be securely caught

in the fabric. The raw edge of the

over edged material shall be

properly trimmed.

a. Overedge stitch the inseam and

503

EFd-1

6-10

70/2

70/2

outseam of front trouser, also the

or

edge of right front. The overedge

504

stitching of the inseam of left

front shall extend from bottom of

trouser to fly notch. The overedge

stitching of the outseam of fronts

shall extend from the bottom notch

of side pocket to bottom of trouser

leg.

b. Overedge stitch inseam and

503

EFd-1

6-10

70/2

70/2

outseam of back part of trousers.

or

The side pocket stay piece, with

504

the bottom edge turned up, may be

attached to the outseam in the

overedge operation.

c. Overedge stitch crotch seam,

503

EFd-1

6-10

70/2

70/2

seat seam and raw edge at the left

or

end of waistband.

504

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business