MIL-DTL-43415D

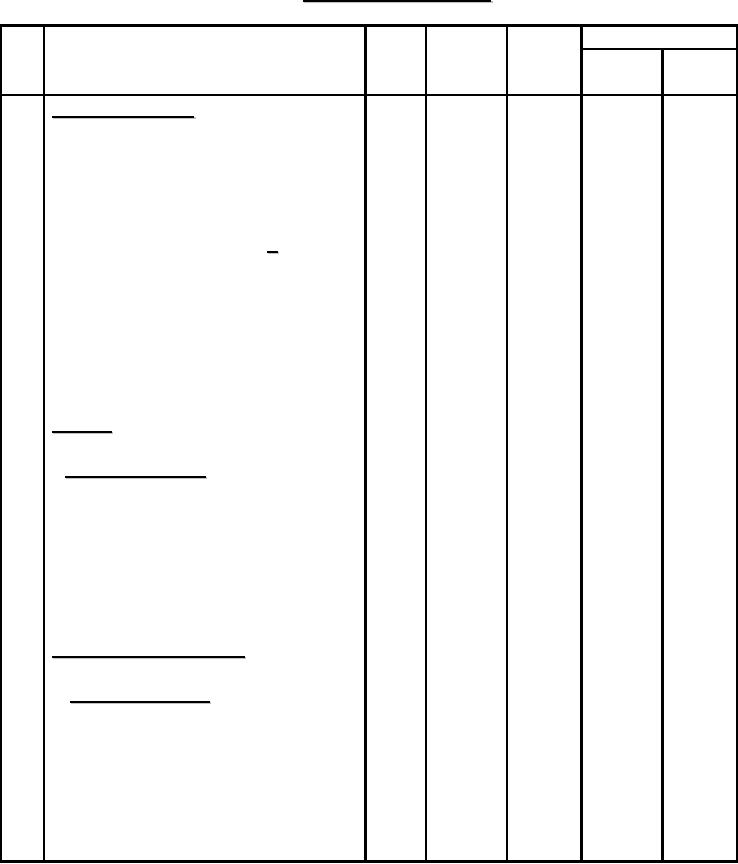

TABLE III. Manufacturing requirements - continued

Seam &

Stitches

Thread

Stitch

Stitching

per

Bobbin/

No.

Operation

Type

Type

Inch

Needle

Looper

12. Set inner body band. (cont'd)

f. Turn binding to inside of cap and stitch

301

EFb-1

6-8

A black

A black

through all plies 1/16 to 3/32 inch from top

turned edge of binding, with bottom edge of

front stay caught in the binding and side edge

of label caught in the stitching 1 + 1/2 inches

to the right or left of center back seam. The

binding shall finish 1/4 to 5/16 inch wide on

outside of band. The joining seam of the

binding ends shall be in line with back seam

of band. The polished side of the binding

shall be showing.

13.

Set visor.

Finished appearance. The visor shall be

uniformly set and the band shall not be

distorted or twisted in the setting.

Position visor to inside of inner body band

301

LSa-1

6-8

16-4

16-4

with visor notch centered with front of cap

and stitch visor to cap.

14.

Make and attach sweatband.

Finished appearance. The abutted edges

of sweatband and sweatband welt shall be

centered (1/4 inch tolerance) with the center

back seam of cap. The sweatband shall

finish smooth and flat without distortion to

provide a comfortable fit.

110p19" style="font-size:12px">19

Downloaded: 2014-09-28T11:48Z

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business