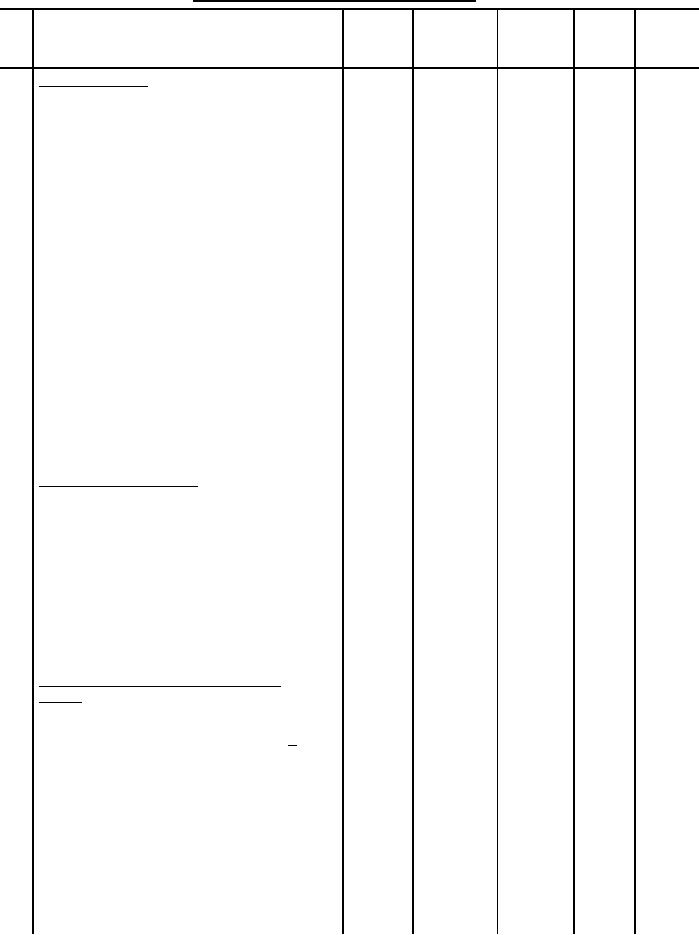

MIL-DTL-28919B(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

20

Join outseams.

Finished appearance. Outseams

shall be carefully joined with

notches matching, and without

twists, puckers or pleats. The

seams shall start and finish evenly

and lie smooth and flat.

a. Join the outseam with a 3/8

301

SSa-1

10-14

30/3

30/3

inch seam, matching the notches as

or

indicated by marks on the patterns,

401

SSa-1

10-14

30/3

30/3

joining the back pocket bearer to

the front at the side seam and

catching the side pocket stay with

its bottom end turned (if not

previously caught in overedge

operation) (see operation 4.b).

b. Spread open the outseams from

top edge of trousers to bottom and

press smooth and flat with a heated

pressing machine with the pocket

stay folded and pressed flat over

the open seam.

21

Finish side pockets.

a. Turn under the back edge of

301

SSc-1

10-14

50/3

50/3

side pocket and position in line

and

with the folded edge of the stay

301

SSe-2

10-14

50/3

50/3

piece and stitch pocket to stay

(b)

piece 1/4 to 3/8 inch from edge

along the side seam allowance.

Continue stitching along the side

seamed edge of pocket to folded

edge of pocket and securely

backstitch end of stitching.

22

Attach waistband and set belt

loops.

Finished appearance. The finished

waistband shall measure 1-3/4 + 1/8

inches wide. The loops shall be

positioned as follows:

One loop on each front as indicated

by the mark on the pattern.

One on each side, aligned with the

outseam at the back.

One centered between outseam and

seat seam as indicated by the mark

on the patterns.

24

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business