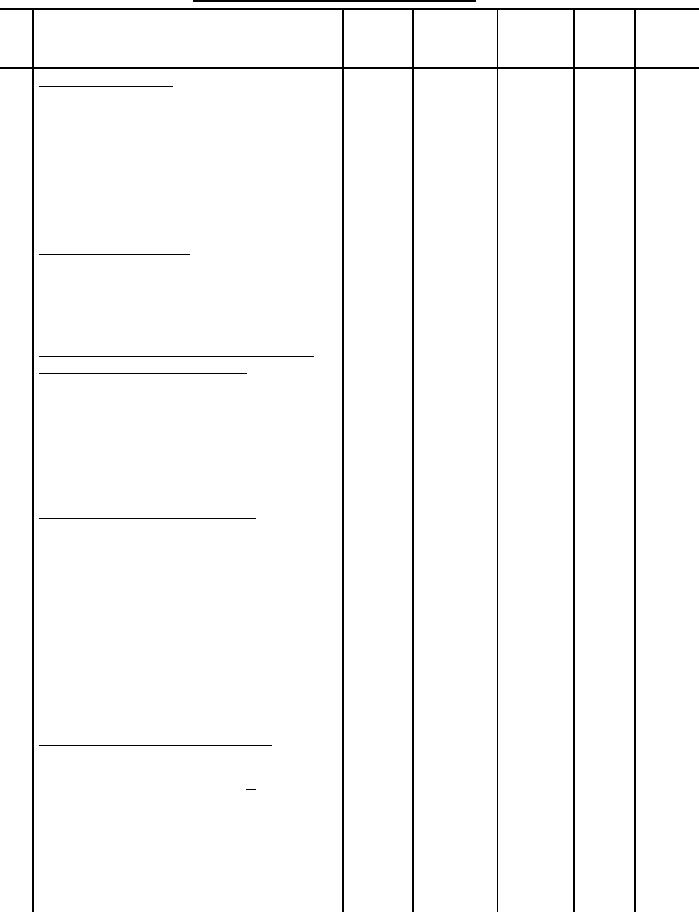

MIL-DTL-28919B(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

30

Finish waistband.

a. Top stitch the spread open

301

LSbd-2

12-16

50/3

50/3

waistband seam 1/16 inch below the

(show

joining seam, catching the

finished

waistband lining (with ends of

seam)

center back folded in) and the top

of pockets in the stitching. The

stitching shall not extend across

the fly.

31

Assemble fasteners.

a. Attach slider and with ends of

slide fastener chain even, securely

staple bottom end of chain

together.

32

Press seams (with heated pressing

iron or pressing machine).

Finished appearance. The seams

shall finish smooth and flat

without pleats, puckers or twists.

a. Spread open the seat and crotch

seams from top of waistband to fly

notch and press smooth and flat.

33

Stitch right fly extension.

Finished appearance. In the

finished trousers the right fly

lining extension shall finish not

less than 1/2 inch beyond juncture

point of the right and left inseam.

a. Turn the raw edges and end of

301

SSac-3

12-16

50/3

50/3

the right fly lining extension and

(b), (c)

or

machine stitch or hand fell to each

and (d)

Hand

side of the open crotch seat seam,

SSac-3

6-8

50/3

catching the turned under end in

(b), (c)

the stitching.

and (d)

34

Finish belt loop attachments.

Finished appearance. All belt loop

openings shall measure 2 + 1/8

inches from bartacking of loop to

folded edge. The tacking shall

extend the width of the loops, not

beyond. All loops shall be

vertically straight. The center

back loop shall be centered on the

waistband and seat seams.

29

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business