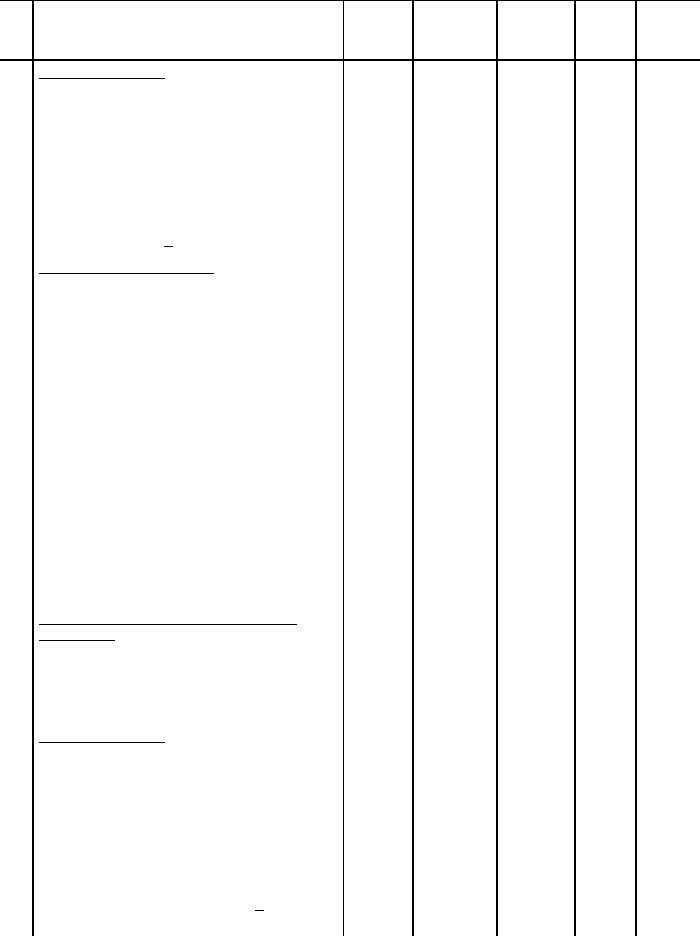

MIL-DTL-28902C(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

Press waistband.

24

a. Turn out front end of left and

right waistband, forcing out the

corners. Turn waistband lining to

inside and press along the top edge

of waistband. Trouser waistband

lining shall not be exposed beyond

top edge of waistband.

b. Finished width of waistband

shall be 1-3/4 + 1/8 inches.

25

Attach hooks and eyes.

Finished appearance. In the

finished trousers, when hook and

eye is engaged, the closure shall

not bulge, pucker or twist.

a. Position the hook at the center

(1/4 inch off center tolerance) of

the left waistband with the rolled

edge of hook aligned with the slide

fastener scoops. Attach hook to

left waistband through a suitable

reinforcement.

b. Position the eye at the center

of the right waistband aligned with

slide fastener scoops and to

corres- pond with hook and left

waistband. Attach eye to right

waistband through a suitable

reinforcement.

26

Stitch pockets to lower edge of

waistband.

a. Stitch top end of back pockets

301

SSa-1

12-16

50/3

50/3

to waistband seam allowance with

or

pockets properly positioned and

101

smoothed out.

Finish left fly.

27

Finished appearance. The base of

the fly shall be finished so as to

avoid twisting, pleating or

puckering. The joining seam of

left fly to front shall not be

exposed on outside of trouser.

a. Seam back edge of left fly to

301

SSa-1

12-16

A

A

front from notch to top of

(silk

waistband uniformly 1-1/2 + 1/8

)

inches from front edge to fly.

21

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business