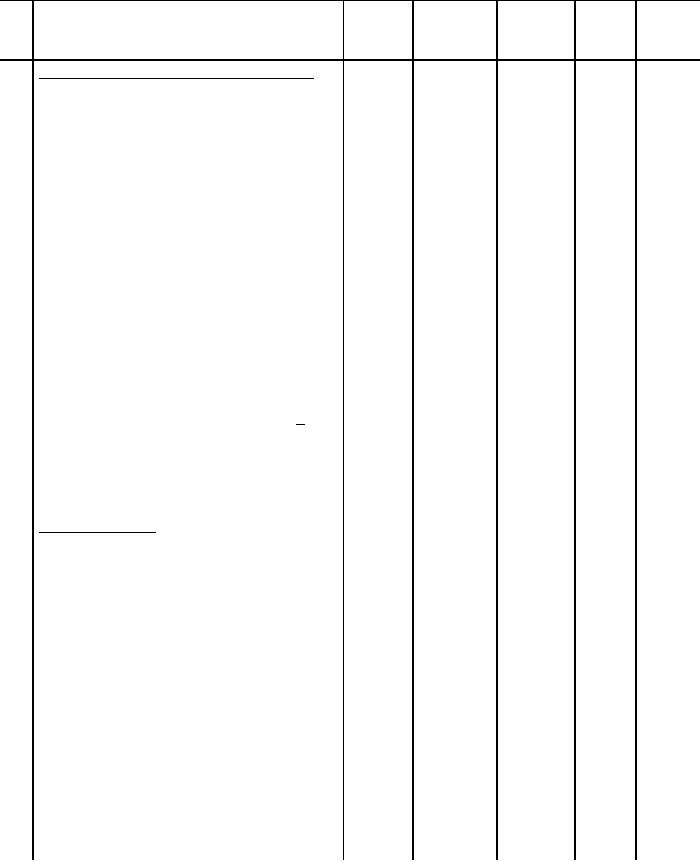

MIL-DTL-28902C(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

8

Make buttonhole tab for right fly.

Finished appearance. The

buttonhole tab shall finish without

distortion, with the buttonhole

stitching securely caught in the

fabric and with the seams finishing

at the edge of the tab.

a. The tab shall be made of two

plies of basic material.

b. Seam the plies together at top,

301

SSe-2

12-16

A

A

front and bottom edges with 3/16 to

(a)

1/4 inch seam and turn, forming out

all edges.

c. Topstitch the tab 1/16 to 1/8

301

SSe-2

12-16

A

A

inch from the seamed edges.

(b)

d. Make a 5/8 inch long,

Button-

48 min

A

A

horizontal, eyelet-end, taper-bar

hole

per

(silk

(silk

type buttonhole through the center

button-

)

)

of tab with edge of eyelet 1/2 +

hole

1/8 inch from finished end of tab.

(incl.

The buttonhole shall be well worked

tack)

over gimp to fit a 22 line button

and with the purling on inner side

of tab.

Make right fly.

9

Finished appearance. The right fly

shall finish without bulkiness,

twists, puckers, or pleats.

a. The fly shall consist of one

ply of basic material, a buttonhole

tab and the lining.

b. Position the buttonhole tab on

the outside of the fly, with raw

edges even and the upper finished

edge of tab in line with the notch

in the upper front edge of fly.

c. Seam fly and lining together

301

SSe-2

12-16

40/3

40/3

3/16 inch from front edge. The

(a)

seam shall extend from the bottom

edge of fly up to the upper edge of

buttonhole tab, catching the tab in

the stitching.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business