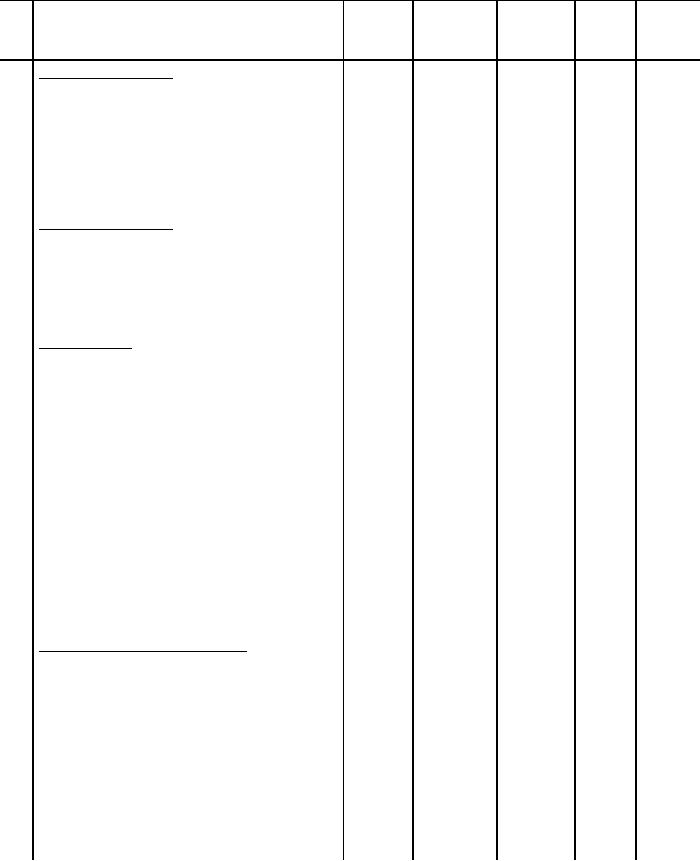

MIL-DTL-28902C(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

28

Finish right fly.

a. Turn to the inside and

301

SSe-2

12-16

40/3

A

edgestitch right fly lining front

(b)

and top edges of right fly and

(show

through the buttonhole tab 1/8 inch

finished

from edge. The lining shall not be

seams)

exposed on the outside of the

trousers.

Finish right fly.

28

(cont'd)

b. Turn under the raw edge of fly

301

LSg-2

12-16

A

40/3

lining and raise stitch the fly

(b)

(silk

(silk

joining seam, catching the turned

)

)

under portion of lining and slide

fastener tape in the stitching.

29

Join inseam.

Finished appearance. Inseams shall

be carefully joined with notches

matching and without twists or

puckers. The seams shall start and

finish evenly and be smooth and

flat.

a. Join the inseam from the bottom

401

SSa-1

12-16

A

A

edge of the legs to the crotch with

the notches matching as indicated

by marks on the patterns, forming

an outlet tapering the seam

allowance of the back from 1-1/8

inches at the crotch to 3/8 inch at

the knee notch.

b.

Press the inseam open.

30

Join crotch and seat seam.

Finished appearance. The crotch

and seat seams shall be joined with

proper tension, resulting in suffi-

cient elasticity of seam to

counter- act strain encountered in

sitting or stooping. In the

joining of the seat seam, the

inseams shall meet.

a. Measure waist to proper size

before joining crotch, seat, and

waist seam.

22

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business