MIL-DTL-82149C(MC)

Manufacturing requirements - Continued.

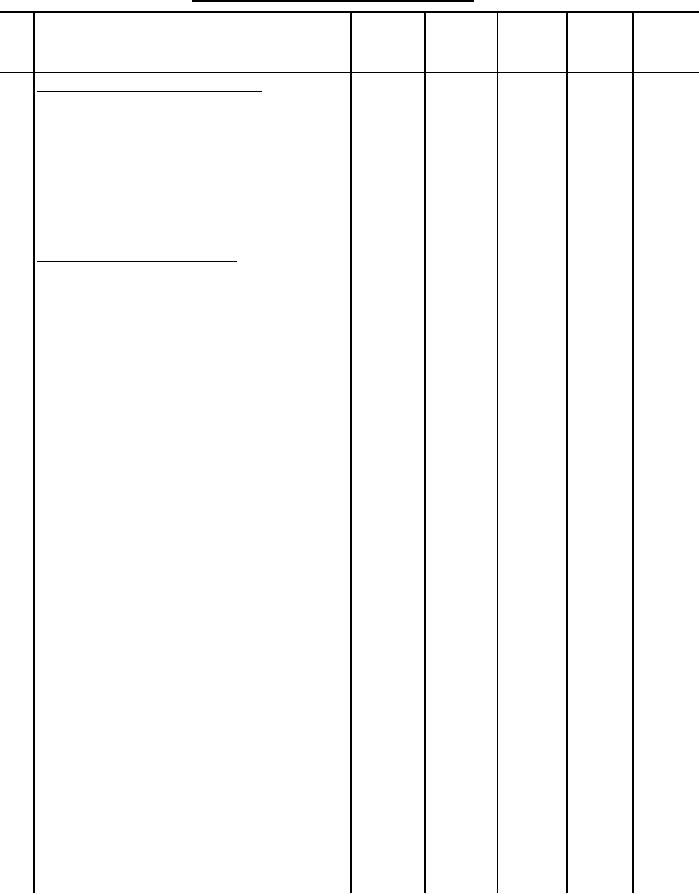

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

20 Assemble collar interlining.

(cont'd)

b. Seam the plastic, polyester and

301

SSa-1

12-16

A

A

buckram together 1/8 to 3/16 inch

from all edges and trim the polyester

even with the edges of the buckram.

The polyester cloth shall be

positioned on the inside and the

plastic on the outside.

21 Pipe outer ply of collar.

Finished appearance. The piping

shall extend at upper, lower and side

edges of the outer ply and shall be

uniformly stitched without twists,

gathers, puckers or pleats.

a. The outer ply of the collar shall

consist of one piece of the material

specified in 3.3.2, piped with

material specified in 3.3.5 and

3.3.5.1.

b. Seam a 5/8 to 3/4 inch wide strip

301

SSaa-1

12-16

A

A

of piping to outer ply 1/8 inch from

(silk)

(silk)

bottom and side edges, leaving a 3/4

to 1 inch extension on each end of

piping at lower edge of collar. The

extension ends of piping shall be

approximately 3 inches from the

pointed end of collar. Seam the

vinyl piping to the upper collar edge

with collar abutted against cord

edge.

c. Join extensions together as close

301

SSa-1

12-16

A

A

as possible to outer ply.

(white) (white)

d. Trim the extension piping to 1/4

301

SSa-1

12-16

A

A

inch from the seamed edge. Spread

(silk)

(silk)

open joining of extension and stitch

to collar along seam joining piping

to outer ply.

e. Turn back the piping and outer

301

12-16

A

A

ply, uniformly working the folded

(silk)

(silk)

edge of the piping beyond the edges.

Topstitch the outer ply uniformly

3/16 inch from the folded edge of

piping.

19

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business