MIL-DTL-82149C(MC)

Manufacturing requirements - Continued.

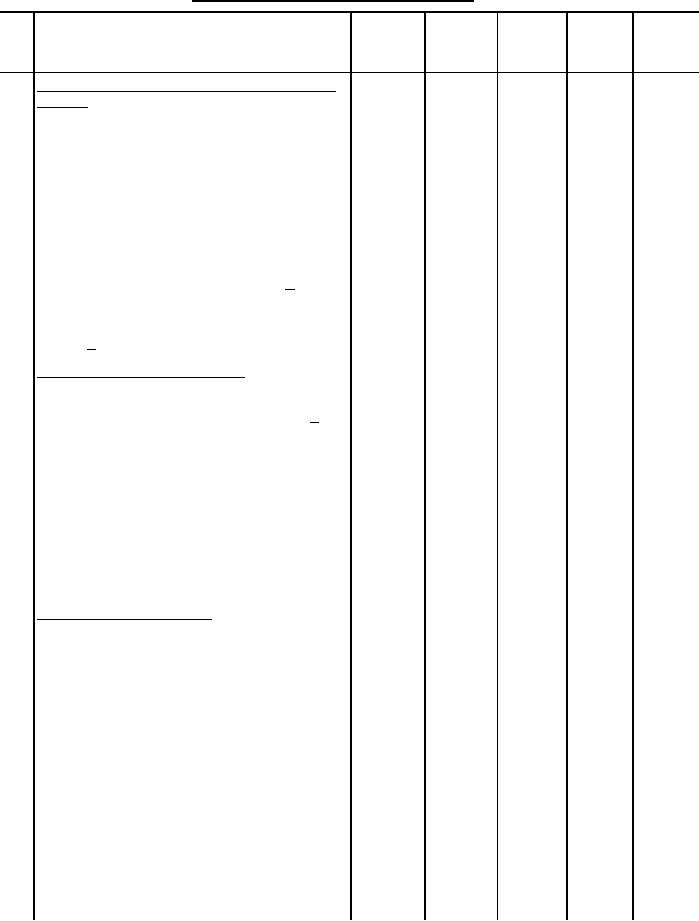

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

4

Make coat hanger and lining securing

straps.

Finished appearance. The coat hanger

and lining securing straps shall

finish 1/4 to 3/8 inch wide.

a. Fold the 1-1/8 inch wide straps

301

EFp-1

12-16

A

A

of lining material in half

lengthwise. Turn the edges to the

inside and seam 1/16 inch from the

turned edges.

b. Cut the coat hanger 3-3/4 + 1/4

inches long.

c. Cut the lining securing straps

4-1/2 + 1/4 inches long.

5

Make collar eyelet covers.

Finished appearance. The collar

eyelet covers shall finish 1-3/4 +

1/8 inches wide.

a. Turn under the side edges of the

301

EFa-1

12-16

A

A

collar eyelet covers and stitch 1/8

(each

inch from the folded edges, catching

side

the turned under portions in the

edge)

stitching.

b. Fold each cover in half across

301

SSa-1

12-16

A

A

the width and seam 1/16 inch from the

folded side edges.

6

Make underarm shields.

Finished appearance. The shields

shall finish smooth and flat without

puckers, pleats, gathers, or other

distortions.

a. Position the two plies of the

301

SSa-1

12-16

A

A

material for the underarm shields

with edges even. Seam the two plies

together along the curved side and

bottom edges 3/8 inch from the edges.

b. Turn the shield right side out,

working out completely the seamed

edges.

c. Press the shields smooth and flat

with heated pressing iron or pressing

machine.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business