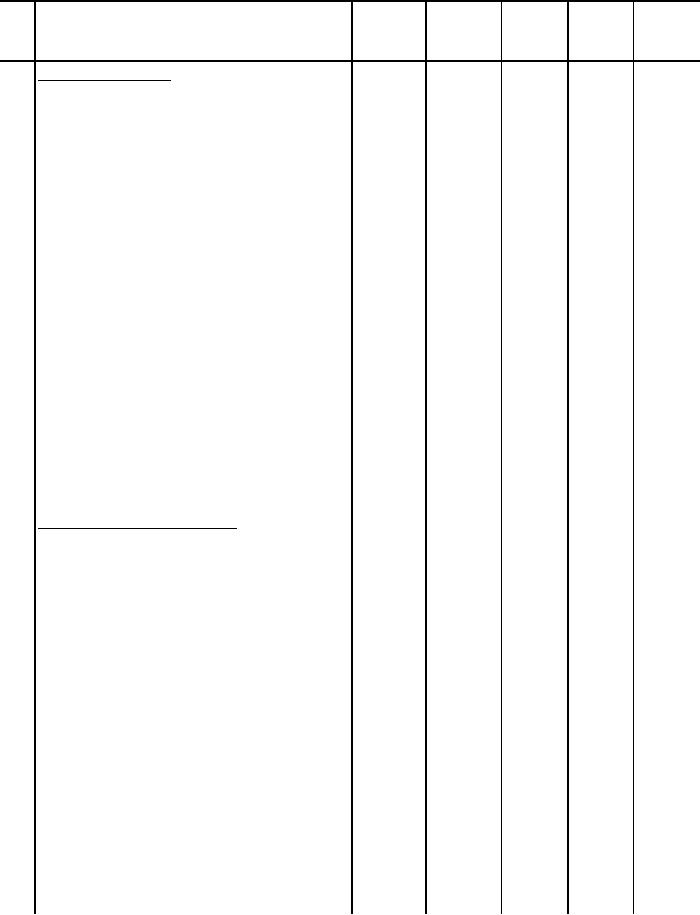

MIL-DTL-82193C(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

4

(cont'd)

Make coat fronts.

e. Position the haircloth

304

FSe-1

4-8

70/2

70/2

reinforcement piece at the top front

corner of the haircloth section on

inner side of the haircloth sections

and stitch together with vertical

rows of stitching 3/8 to 1/2 inches

apart.

f. Abut or overlap (1/8 inch) and

304

FSe-1

4-8

70/2

70/2

stitch together the edges of the

chest dart, upper waist dart, and

lower waist dart on padding. The

abutted or overlapped edges may be

stitched together.

g. Position haircloth section and

304

FSa-1

4-8

70/2

70/2

padding section on underside of front

section and quilt all parts together

with vertical rows of stitching 3/8

to 1/2 inches apart and curved rows

toward the armhole. The shoulder

portion shall be left open to

accommodate the shoulder pad.

h. Steam shrink fronts and press dry

to conform to shape of body.

5

Assemble shoulder straps.

Finished appearance. The shoulder

straps shall be assembled without

twists, gathers, puckers, pleats or

raw edges. Edges of finished

shoulder straps shall be uniformly

1/8 inch from outer row of

embroidery. The eyelets shall be

well worked with the purling on the

outside of shoulder straps and shall

finish with a 1/8 inch diameter

opening. The straps shall be uniform

in size and shape. The rayon lining

shall not be exposed on outside of

straps.

a. Form a 1/2 to 3/4 inch wide

vertical pleat to the outside in the

center of rayon lining.

b. Secure the pleat with a row of

301

SSa-1

10-14

A/3

A/3

stitches on both ends of the pleat,

or the pleat may be pressed in lieu

of tacking

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business