MIL-DTL-82193C(MC)

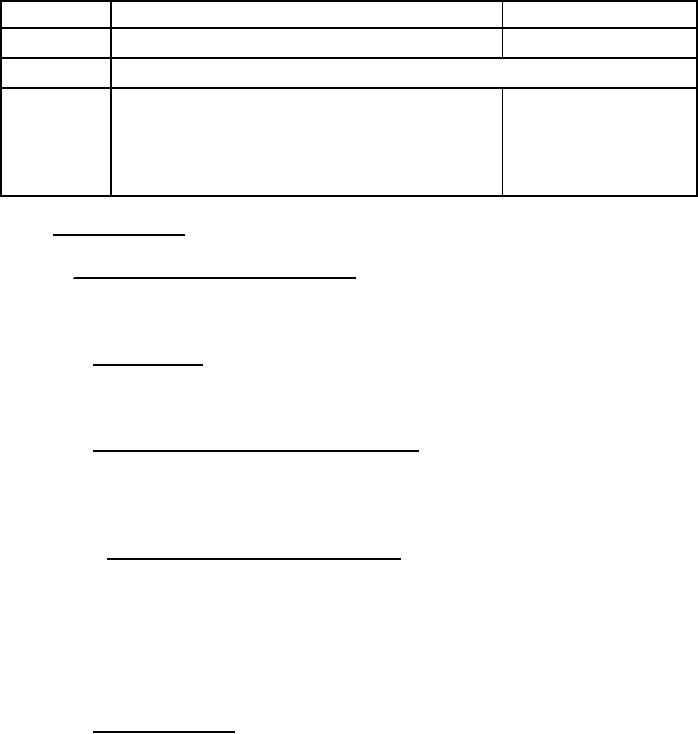

ITEM

PATTERN NOMENCLATURE

NO. OF CUT PARTS

28

Collar interlining

1

Shapers and Markers

29

Button and buttonhole marker and

front shaper

30

Finished sleeve patch and button

marker

31

Finished shoulder straps

3.6. Construction.

3.6.1 Manufacturing requirements. The jacket shall be

manufactured in accordance with operation and the stitch, seam,

and stitching types specified in Table I.

3.6.1.1. Operations. The contractor is not required to follow

the exact sequence of operations as listed in Table I, but all

operations specified shall be used to manufacture the jacket.

3.6.1.2. Stitches, seams and stitchings. The stitch, seam, and

stitching types specified in Table I shall conform to

FED-STD-751. The number of stitches per inch as specified in

Table I indicates the minimum and maximum number permitted.

3.6.1.2.1 Ends of seams and stitching. Ends of seams and

stitchings, except ends of a continuous line of stitching

produced with 301 stitch type, when not caught in other seams or

stitchings shall be backtacked not less than 1/4 inch. Thread

breaks (all stitch types) shall be secured back of the break and

ends of a continuous line of stitching shall overlap not less

than 1/2 inch.

3.6.1.3. Shade marking. The component parts of jacket, cut from

one piece of basic and lining materials, including pairs of

sleeve lining when cut from ends, shall be marked to ensure a

uniform shade and size throughout the garment. Parts cut from

ends that are sized shall be identified from size. The use of

tickets with metal fastening device is prohibited on rayon

lining. Any method of shade marking may be used except:

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business