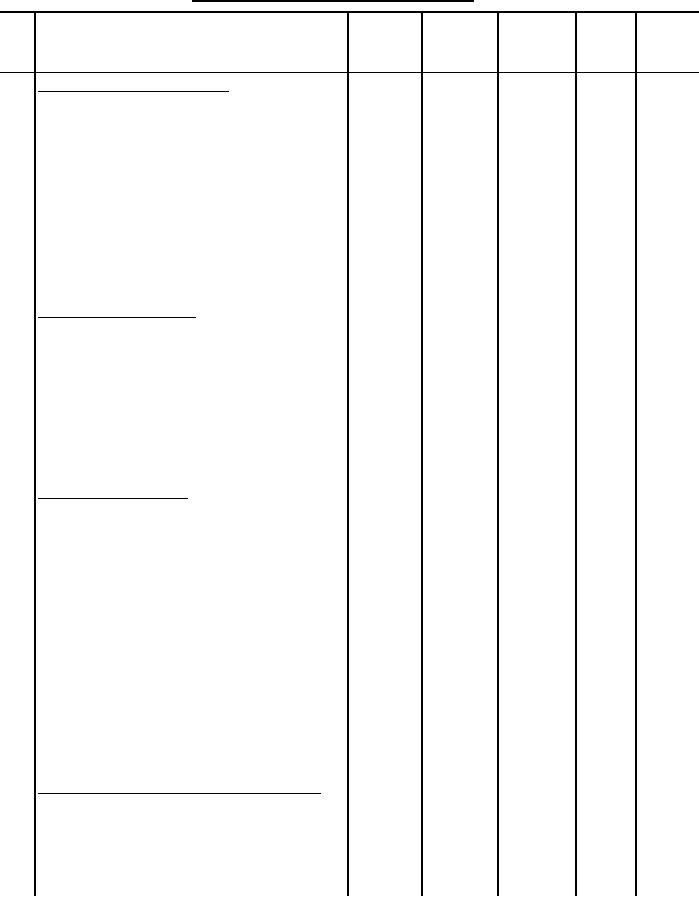

MIL-DTL-29451B(MC)

Manufacturing requirements - Continued.

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

20 Make waistband assembly.

a. Sew a shell extension facing

301

SSa-1

10-12

70

70

piece to each end of the knit

waistband with a 3/8 inch seam. The

seams shall face front edge.

b. Fold the waistband assembly in

half lengthwise and press flat with a

heated steam iron or press.

NOTE: The waistband shall measure 3

inches in width after joining to the

jacket.

21 Join shoulder seams.

a. Position the front to the back

301

SSa-1

10-14

70

70

with the raw edges even at the

or

shoulders and join with a 3/8 inch

401

seam.

b. Press the shoulder seams toward

301

SSa-1

10-12

70

70

the front with a hot steam iron or

press and topstitch front 1/8 inch

from shoulder seam.

22 Set shoulder strap.

a. Position the shoulder strap with

the pointed end of the strap facing

toward the edge of the neck and with

the raw edge in line with the

armhole. The back finished edge of

the strap shall be 1/2 inch behind

and in line with the shoulder seam.

Correct position of the button to be

in alignment with shoulder strap

button- hole and when buttoned, there

shall be no distortion of strap or

shoulder.

b. Seam the shoulder strap to the

301

SSa-1

10-12

70

70

jacket 1/8 inch from the armhole

or

edge.

401

23 Attach hanger braid and size label.

a. Position the hanger braid and the

301

SSa-1

10-12

70

70

size label to the inside center back

or

of jacket at the lower edge of the

401

collar and seam to the knit collar

with a 1/8 inch seam.

19

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business