MIL-DTL-29451B(MC)

Manufacturing requirements - Continued.

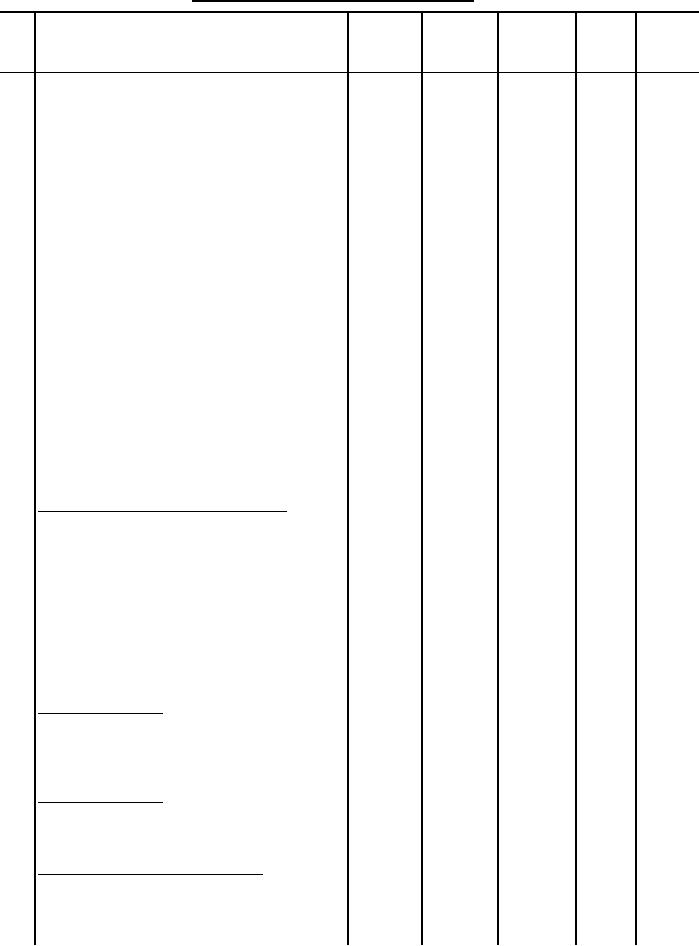

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

301

LSq-2

10-12

70

70

a. Join side back to respective side

of center back with a 3/8 inch seam.

or

(a)

401

b. Fold the joining seam toward the

301

LSq-2

10-12

70

70

center back and topstitch from bottom

(b)

of jacket to the point where the

curved/rounded parts of bi-swing back

begins, through all plies with 1/8

inch topstitch. Continue the 1/8

inch topstitch through the fold of

center back to notch at shoulder

catching only the two ply fold of the

back on each side of the back forming

the bi-swing back.

c. The formed pleats of the bi-swing

301

SSa-1

10-12

70

70

back shall be tacked across the

shoulder outer raw edge with a 1/8

inch stitch.

d. The pleat of the side back shall

301

SSa-1

10-12

70

70

be sewn with 1/8 inch seam across the

top of shoulder for a distance of 1

inch down the fold of pleat through

all plies.

11 Join elastic to bi-swing pleat.

a. With the wrong side up and the

301

SSa-1

10-12

70

70

back assembly laying flat, position a

1 inch wide strip of elastic 1/2 inch

above the curved part of bi-swing

pleat from left to right side. Tack

the elastic to each side of pleat 1/8

inch from the finished seam of the

pleat. The elastic and back assembly

shall lay flat without twists,

puckers or fullness.

12 Join side seams.

a. Join the fronts and back with a

301

SSa-1

10-12

70

70

3/8 inch seam.

or

401

12 Join side seams.

(cont'd)

b. Press the side seams open with a

hot steam iron or press.

13 Join front facing to lining.

a. The front facing shall be joined

301

SSa-1

10-12

70

70

to the front lining with a 3/8 inch

seam.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business